Dairy Heat Exchanger Applications

Stock and Custom Heat Transfer Equipment

Dairy heat exchanger applications require precision-engineered systems to maintain the integrity of milk and dairy products. These systems ensure efficient temperature regulation for sensitive materials, adhering to rigorous health and safety standards such as 3-A sanitary guidelines. We are committed to partnering with you to create the most effective, cost-efficient, and practical solutions for your heat transfer needs in pasteurization, cooling, and processing.

- Pasteurization: Heat exchangers rapidly heat milk to kill pathogens while preserving nutritional value, essential for safe dairy products.

- Cooling: Efficiently cool pasteurized milk or cream to prevent spoilage and maintain quality in dairy processing lines.

- Clean-in-Place (CIP): Dairy Heat Exchangers support sanitization protocols, ensuring high-purity conditions for sensitive food production.

- Plate & Frame: Compact designs with high efficiency, ideal for viscous dairy products like yogurt and cheese, built to 3-A standards.

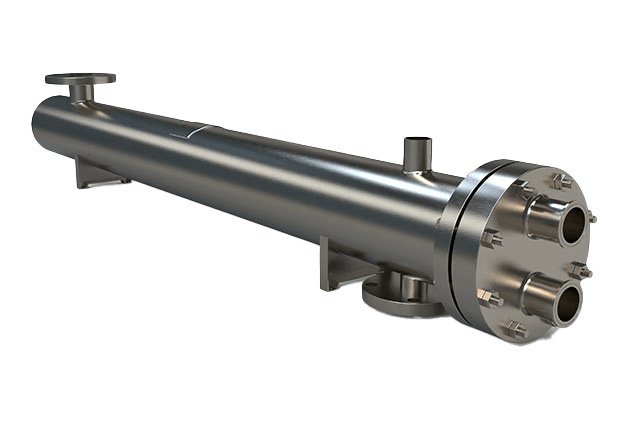

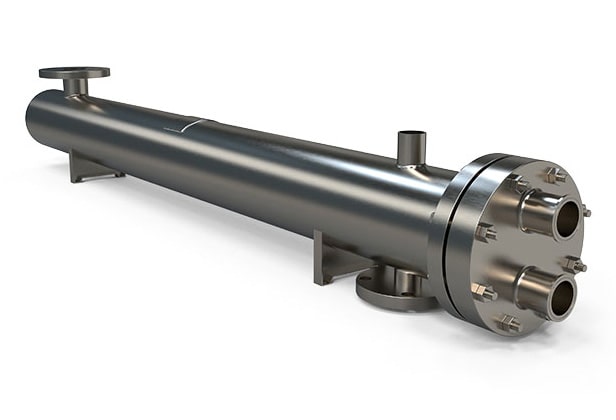

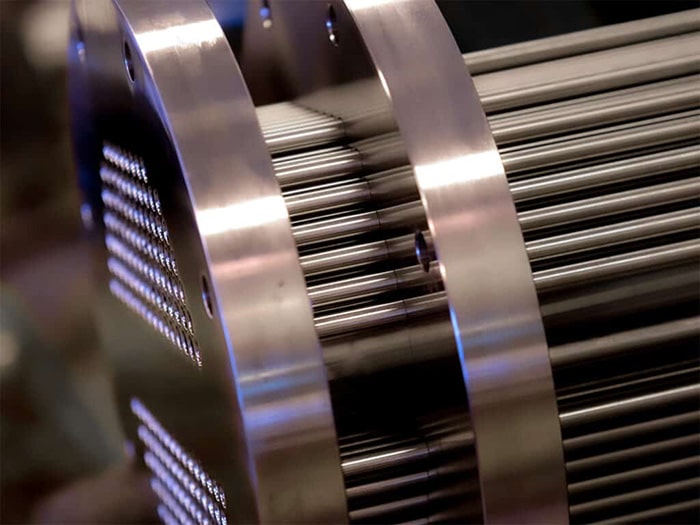

- Shell & Tube: Robust units for high-pressure dairy applications, offering durability and easy maintenance in milk processing.

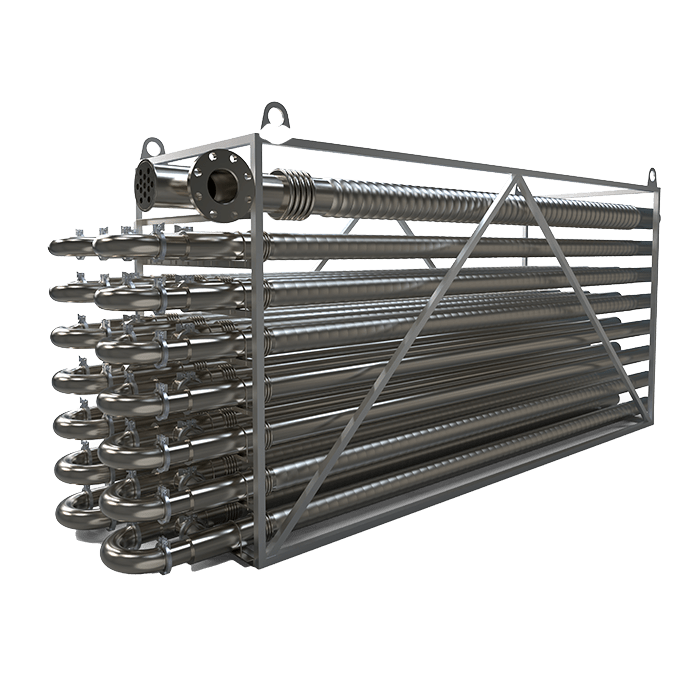

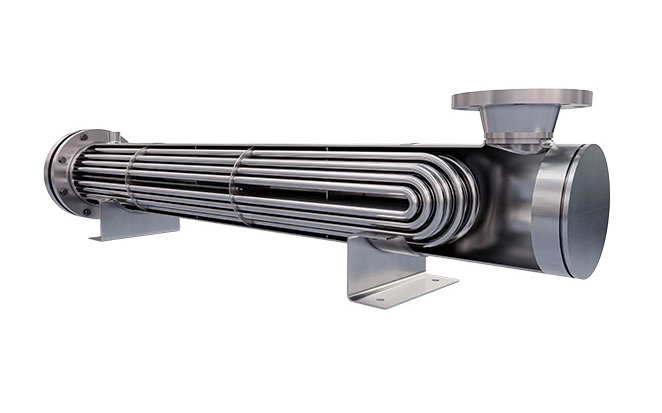

- Tube-in-Tube: Gentle handling for particulate dairy products, customizable with sanitary fittings for optimal performance.

Heating

High efficiency and suitable for various sanitary applications

- Milk Pre-Heating

- Cream Processing

- Yogurt Fermentation

Cooling

Highest cooling performance in heat transfer

- Milk Post-Pasteurization

- Cheese Curd Cooling

- Ice Cream Mix

Pasteurization

Precise temperature control for pathogen reduction

- HTST Milk

- Extended Shelf Life

- Cream Products

CIP Systems

Automated cleaning for sanitary compliance

- Plate & Frame

- Shell & Tube

- Tube-in-Tube

Comprehensive Dairy Solutions

Since our inception, we've focused on providing top-tier heat transfer solutions, with a particular emphasis on Dairy Heat Exchangers critical for industries where hygiene is paramount. Our expert engineers will guide you through the selection of the most suitable heat exchanger type for your application, including shell & tube, plate & frame, and tube-in-tube designs, paired with Advantage Chillers for optimal cooling.

Each of these systems is designed to meet rigorous sanitation standards required in the dairy sector, such as 3-A compliance. Shell & tube exchangers offer robust performance for high-volume milk processing, while plate & frame units provide compact efficiency for viscous products. Tube-in-tube designs ensure gentle handling of sensitive dairy flows. Integrated with Advantage Chillers, including glycol models for precise low-temperature control, these solutions support everything from farm milk cooling to advanced UHT processing.

We offer both off-the-shelf and custom-engineered heat transfer solutions at competitive prices. Our mission is to assist you through every phase, from sizing and selection to production, ensuring that your dairy processing equipment exceeds expectations for efficiency, safety, and longevity.