Dairy Heat Exchangers for Butter Processing

Butter manufacturing requires temperature management for cream pasteurization, ripening, churning, and washing. Plate-and-frame exchangers pasteurize at 85–95°C, tube-in-tube gently heat for ripening at 15–20°C, shell-and-tube process viscous butter masses, and Advantage chillers cool wash water or final product to 10–15°C—all reducing fouling from butterfat while maintaining 3-A sanitation standards.

Applications

- Cream Pasteurization: Heat exchangers pasteurize raw cream at 85–95°C to eliminate pathogens before cooling for ripening or churning.

- Ripening Temperature Control: Gentle heating maintains 15–20°C for cultured butter fermentation, developing diacetyl flavors evenly.

- Churning Support: Pre-churn cooling or heating optimizes cream temperature (8–14°C) for efficient fat agglomeration in continuous systems.

- Butter Washing & Cooling: Chillers provide cold water (2–4°C) for washing to remove buttermilk, and cool butter to 10–15°C for working and packaging.

- CIP for Butterfat Residues: Automated CIP removes heavy butterfat buildup using hot alkaline solutions, ensuring hygiene in butter lines.

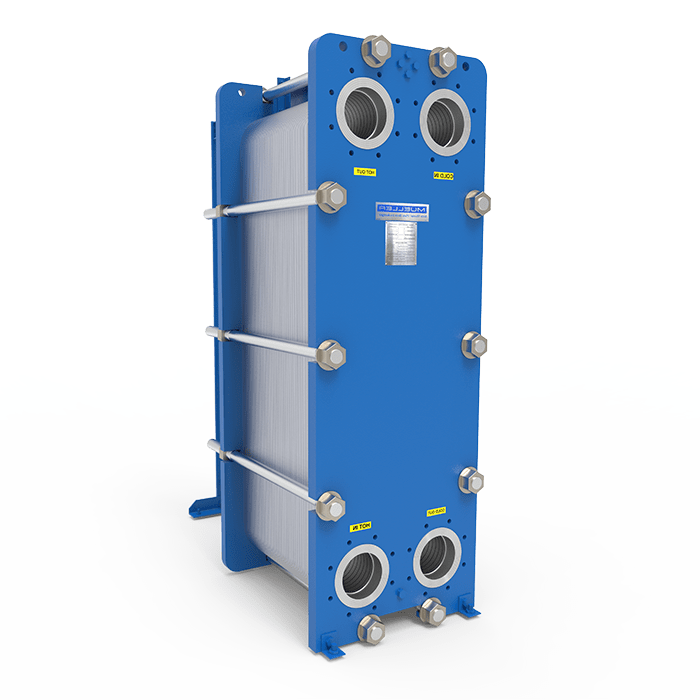

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

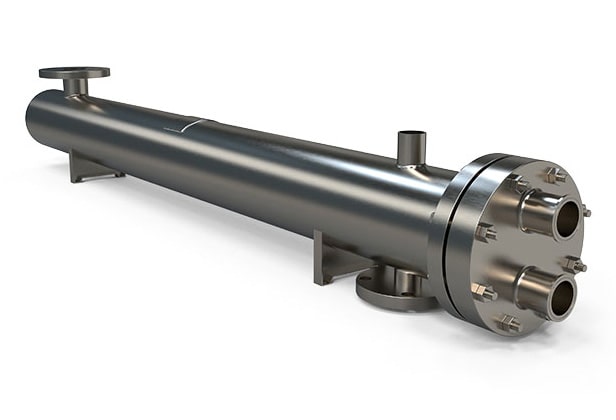

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

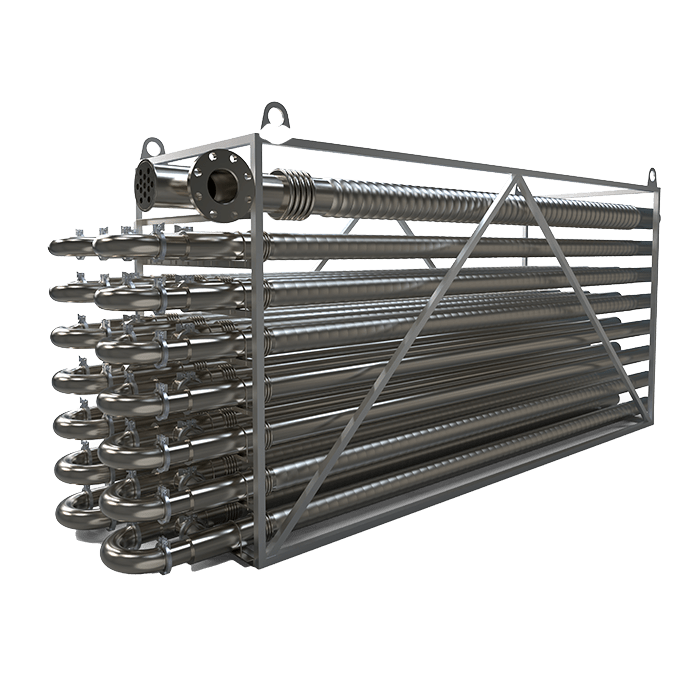

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Butter Processing

Butter production relies on exact temperature sequences to achieve desired spreadability, flavor, and yield. A European butter maker increased churn efficiency by 25% using shell-and-tube exchangers for cream pasteurization and tube-in-tube for controlled ripening, combined with Advantage chillers for precise wash water cooling—reducing water use by 35% and improving texture consistency with no off-flavors over 15 months.

These exchangers feature high-fat tolerant designs with corrugated tubes and wide gaps, 316L stainless steel, and crevice-free construction for easy CIP. Regenerative systems recover heat from pasteurized cream to preheat incoming batches, while PLC monitoring ensures optimal ripening temperatures for cultured varieties. Acid-resistant materials handle lactic cultures in sweet cream butter alternatives.

From traditional batch churns to modern continuous buttermakers, these heat exchangers provide reliable pasteurization, temperature-optimized ripening, and efficient cooling—yielding butter with superior aroma, firmness, and microbial safety for table, baking, and export markets.