Plate & Frame Heat Exchangers for Dairy

Efficiency and ease of maintenance are key in dairy processing. Our plate & frame designs feature clip-on gaskets, expandable frames, and wide-gap plates in 316L stainless to provide high turbulence and heat transfer rates while allowing quick disassembly for inspection—perfect for HTST pasteurization and regenerative cooling in fluid milk plants.

Applications

- HTST Milk Pasteurization: Plate & frame exchangers heat milk to 72°C with 94% regeneration, cooling efficiently for high-volume dairy lines.

- Yogurt Base Heating: Compact designs provide uniform heating to 85–95°C, denaturing proteins for better gel in large yogurt batches.

- Cheese Milk Pre-Heating: Wide-gap plates handle particulates while pre-heating milk to 32°C for rennet addition in cheese vats.

- Cream Cooling: Efficient post-pasteurization cooling prevents separation in high-fat creams for butter production.

- CIP Systems: Exchangers with easy plate removal allow thorough cleaning and inspection in sanitary dairy operations.

Sanitary Design

Hygienic Standards for Dairy Processing

- Electropolished 316L Surfaces

- Crevice-Free Orbital Welds

- Full Drainability & CIP Optimization

3-A Compliance

Certified for Dairy Safety

- Official 3-A Symbol Authorized

- Ra = 32 µin Product Surfaces

- No Threads in Wetted Areas

The Benefits of Plate & Frame Heat Exchangers for Dairy

In high-volume dairy lines, efficiency is paramount to maintaining productivity and reducing operational costs. A yogurt plant boosted throughput by 35% with our gasketed plate & frame exchangers using wide-gap plates, handling viscous bases at 10,000 L/h while cutting energy 25% via 95% regeneration—passing 3-A audits flawlessly. This upgrade not only increased capacity but also improved overall process reliability, allowing for longer run times between cleanings and minimizing downtime in competitive dairy markets.

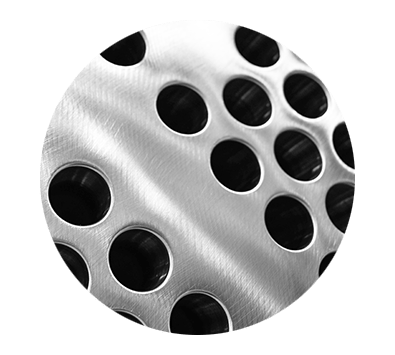

Our plate & frame exchangers feature clip-on EPDM gaskets for quick replacement without tools, titanium plates for enhanced corrosion resistance in aggressive media, and modular frames that allow for easy expansion as production needs grow. Wide channels are specifically designed to reduce pressure drop in flows with particulates or high viscosity, while highly polished surfaces minimize adhesion of milk solids and facilitate faster CIP cycles. These units can integrate seamlessly with flow meters and automated controls for real-time optimization of heat transfer efficiency and energy use.

From compact farm pasteurizers processing small batches to mega-dairy HTST systems handling thousands of liters per hour, our plate & frame exchangers deliver the efficiency, scalability, and cleanability required for modern dairy operations. Built to 3-A sanitary standards with FDA-compliant materials, they ensure compliance with stringent regulations while providing versatile configurations for various dairy products like fluid milk, cultured items, and concentrates—run after run, year after year.