Dairy Heat Exchangers for Ice Cream Mix Processing

Ice cream mix processing requires precise thermal treatment to kill pathogens, emulsify fat properly, and achieve the ideal viscosity and crystallization for smooth texture. Plate-and-frame exchangers deliver efficient HTST pasteurization at 82–86°C, tube-in-tube systems provide gentle pre- and post-homogenization heating, and Advantage chillers rapidly cool mix to 4°C or below—all while minimizing fouling from sugar, fat, and stabilizers in these high-viscosity blends.

Applications

- Mix Pre-Heating: Regenerative plate exchangers raise mix from 4°C to 65–70°C using heat from pasteurized product, saving up to 90% energy.

- HTST Pasteurization: Systems heat ice cream mix to 82–86°C for 15–30 seconds, eliminating pathogens and activating stabilizers while preserving flavor.

- Homogenization Temperature Control: Tube-in-tube exchangers maintain exact 70–75°C inlet to two-stage homogenizers, ensuring small fat globules for creamy mouthfeel.

- Rapid Aging Cooling: Advantage chillers cool pasteurized mix to 2–4°C in seconds using glycol, beginning fat crystallization and improving overrun during freezing.

- CIP for High-Sugar/Fat Mixes: Automated CIP cycles with enzymatic detergents remove stubborn ice cream mix residues, restoring full heat transfer efficiency.

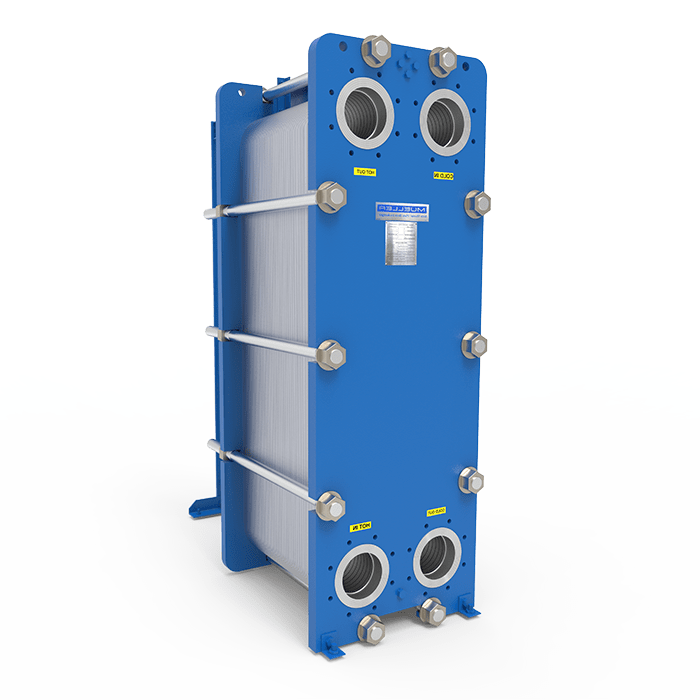

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

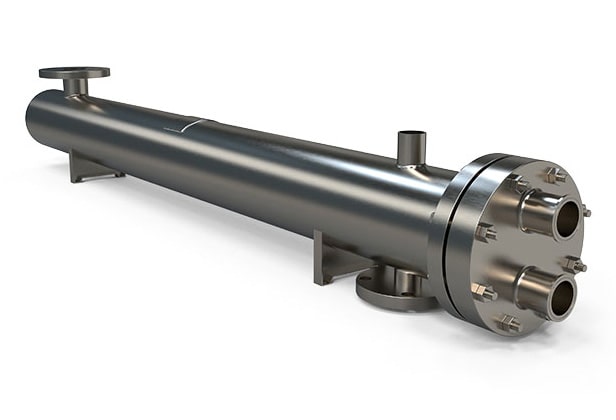

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

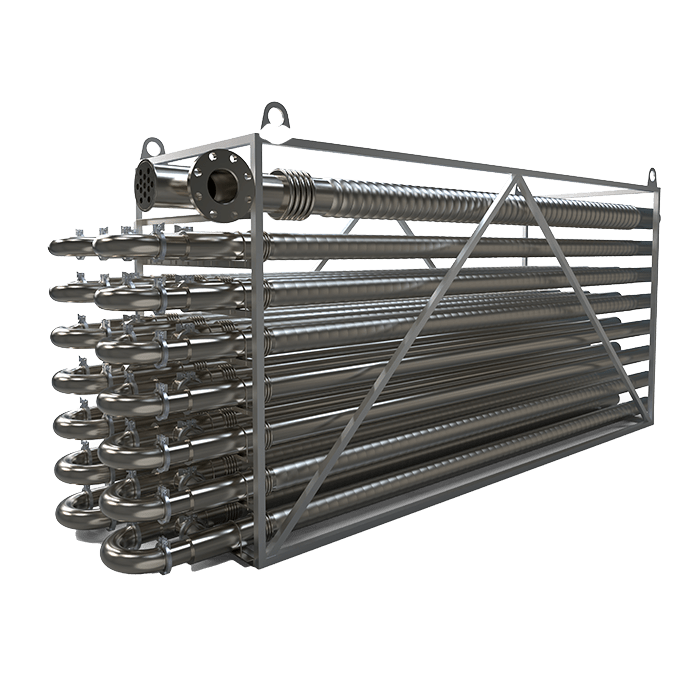

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Ice Cream Production

Ice cream quality begins with flawless mix processing—where temperature control directly affects texture, overrun, and flavor. A major U.S. ice cream manufacturer reduced mix fouling by 80% and increased continuous run time from 8 to 24 hours after installing regenerative plate-and-frame pasteurizers combined with tube-in-tube pre- and post-homogenization exchangers and precision Advantage chillers. The result: smoother mouthfeel, 12% higher overrun, and zero off-flavor complaints over two seasons.

Our systems feature wide-gap plates and corrugated tubes to handle viscosities up to 5,000 cP, electropolished 316L stainless steel, and FDA-approved materials. Automated CIP with enzyme-enhanced detergents removes sugar-fat-protein films in under 90 minutes. Real-time temperature and flow monitoring ensures exact homogenization conditions and rapid aging at 2–4°C for optimal fat crystallization.

From boutique gelato makers to global ice cream brands, these heat exchangers deliver consistent pasteurization, perfect homogenization support, and ultra-fast cooling—creating the foundation for premium frozen desserts with superior creaminess, stability, and shelf life.