Our Dairy Heat Exchangers

Fouling from milk proteins and minerals can reduce efficiency in dairy heat exchangers. Our sanitary designs feature polished 316L stainless channels, wide gaps, and turbulent flow to minimize buildup while enabling fast CIP cycles—maintaining 95%+ thermal performance in high-volume pasteurization and UHT lines for fluid milk, yogurt, cheese, and ice cream mix.

Applications

- Milk Pasteurization: Exchangers heat raw milk to 72°C for HTST, then cool regeneratively to 4°C, recovering 94% energy while complying with PMO standards for 100,000+ L/day plants.

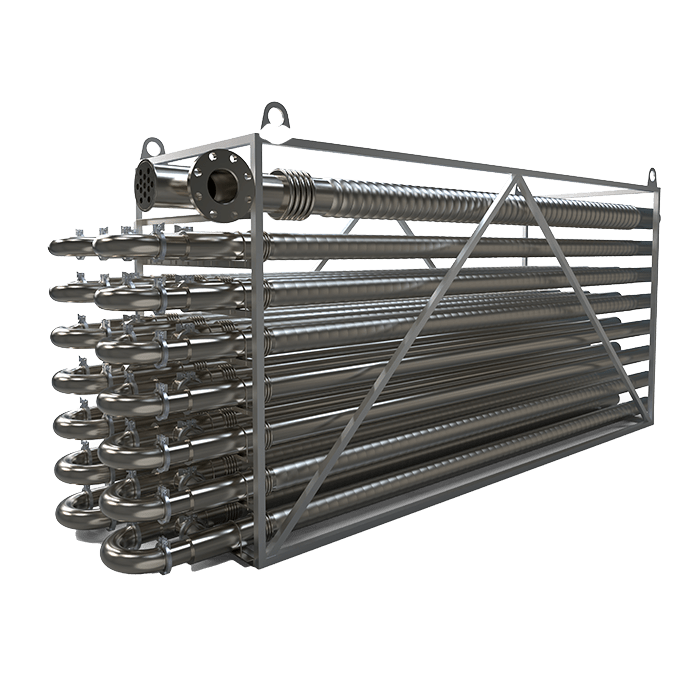

- Yogurt Incubation: Gentle tube-in-tube heating maintains 42°C for Lactobacillus fermentation, preventing hot spots in 20,000 L vats for consistent set and stirred yogurt.

- Cheese Curd Cooking: Shell-and-tube systems raise curd-whey mix to 38°C, expelling whey uniformly for cheddar yields up to 10.5% in 50,000 L batches.

- Ice Cream Mix Cooling: Chillers drop high-fat mix to 4°C post-homogenization, initiating aging with ±0.5°C stability for premium overrun in continuous freezers.

- UHT Sterilization: High-pressure tube-in-tube exchangers flash heat milk to 140°C for 4 seconds, enabling aseptic packaging with minimal flavor change.

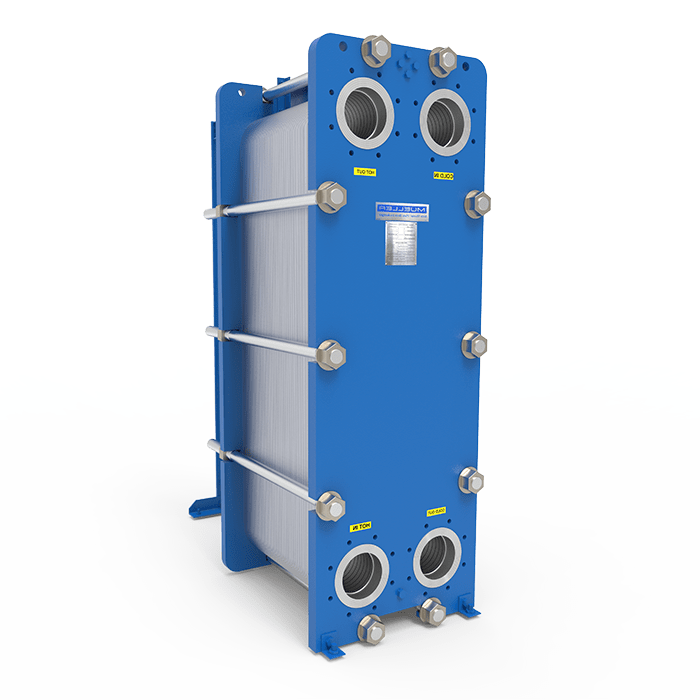

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

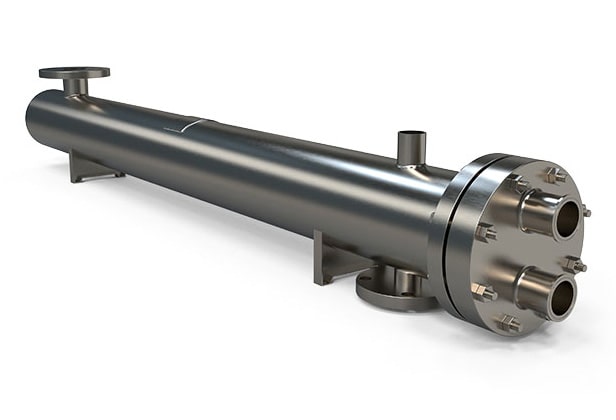

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Our Dairy Heat Exchangers

In dairy processing, exchanger design directly impacts fouling rates and CIP downtime, as milk proteins and minerals can quickly build up and reduce heat transfer efficiency. A fluid milk plant cut cleaning cycles from daily to weekly after switching to our wide-gap plate-and-frame with clip-on gaskets, maintaining 98% efficiency over 72-hour runs and reducing caustic use by 40% while passing 3-A inspections. This improvement not only boosted productivity but also lowered operational costs and environmental impact through reduced chemical consumption.

Our dairy exchangers feature electropolished 316L stainless steel surfaces that resist adhesion, crevice-free welds to eliminate bacteria harbors, and FDA-approved EPDM seals for complete drainability and leak prevention. Regenerative sections in our designs recover up to 94% of heat in high-temperature short-time (HTST) pasteurization lines, significantly cutting energy bills in large-scale operations. Meanwhile, Advantage chillers deliver glycol at ±0.5°C precision for ice builders and low-temp applications, preventing freeze-ups in bulk tanks. SCADA integration allows real-time monitoring of pressure drops and temperatures, enabling predictive maintenance through fouling detection and automatic CIP triggers to minimize unplanned stops.

From farm bulk tanks requiring rapid raw milk cooling to UHT aseptic fillers demanding sterile high-heat processing, our shell & tube, plate & frame, tube in tube, and chillers deliver the sanitary performance, efficiency, and reliability needed for 24/7 dairy operations. These solutions adapt to various scales, from small artisanal cheesemakers to industrial mega-plants, ensuring consistent product quality across fluid milk, cultured products, and concentrates—product after product, year after year.