Dairy Heat Exchangers for Yogurt Processing

Yogurt production requires exact thermal sequences for pasteurization, homogenization, fermentation, and cooling to achieve desired acidity and gel structure. Plate-and-frame exchangers pasteurize milk at 85–95°C, tube-in-tube gently heat to 40–45°C for incubation, shell-and-tube process viscous set yogurt, and Advantage chillers cool to 4–10°C to arrest fermentation—all while managing protein fouling and ensuring 3-A compliance.

Applications

- Milk Base Pasteurization: Heat exchangers pasteurize yogurt milk at 85–95°C for 5–30 minutes, denaturing whey proteins for better gel formation.

- Post-Pasteurization Cooling: Rapid cooling to 40–45°C prepares mix for culture inoculation without premature acidification.

- Incubation Temperature Control: Gentle heating maintains 40–45°C during 4–8 hour fermentation, promoting lactic acid bacteria growth.

- Final Cooling: Chillers cool fermented yogurt to 4–10°C to stop acidification, set viscosity, and prepare for fruit addition or packaging.

- CIP for Yogurt Residues: Automated CIP removes gelled proteins and acids, using enzyme cleaners to maintain hygiene in yogurt processing equipment.

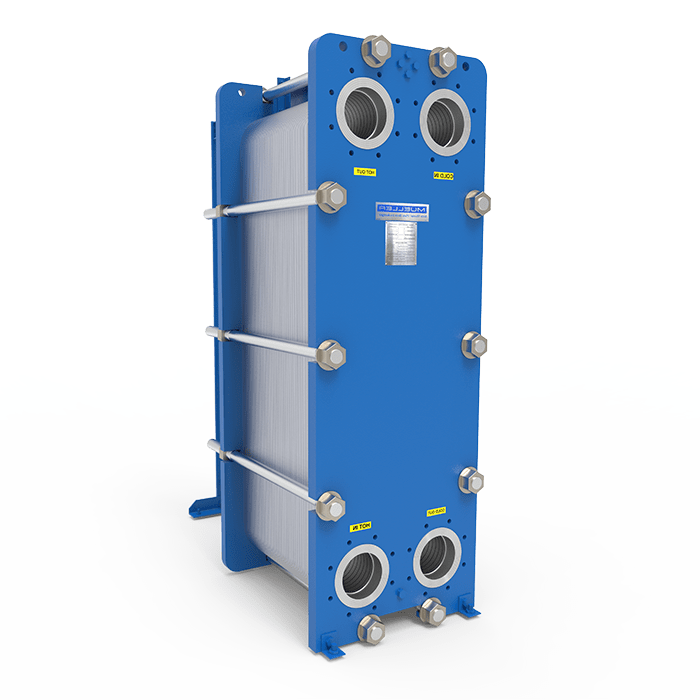

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

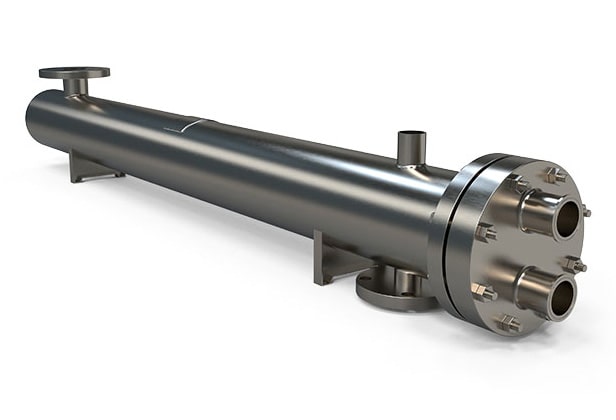

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

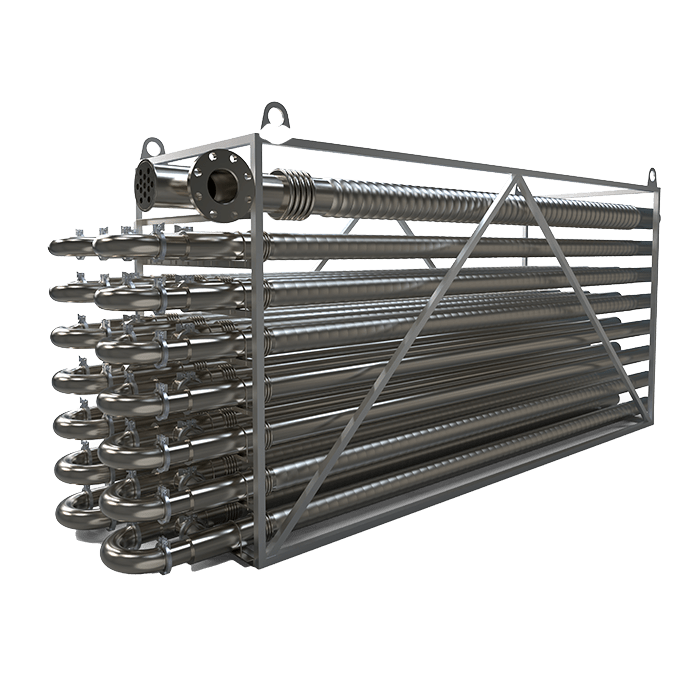

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Yogurt Processing

Yogurt's probiotic benefits and creamy consistency depend on meticulous thermal management. A Greek yogurt producer enhanced gel strength by 22% with high-heat plate-and-frame pasteurization and tube-in-tube incubation heaters, plus Advantage chillers for rapid cooling—cutting production time by 15% and achieving uniform pH with no separation issues over 20 months.

These exchangers utilize acid-resistant 316L stainless, wide-gap plates for thickening yogurt, and regenerative recovery for energy-efficient incubation. Shell-and-tube options process strained Greek varieties under pressure, while PLC systems precisely control fermentation ramps. CIP with specialized acids removes yogurt residues effectively.

From plain set yogurts to fruit-on-bottom styles, these heat exchangers ensure effective pasteurization, stable culturing, and swift cooling—yielding yogurt with superior thickness, tanginess, and shelf stability for health-conscious consumers.