Dairy Heat Exchanger Solutions

Heat Exchangers

Our heat exchangers are designed for the unique demands of dairy processing, offering precise control in heating, cooling, pasteurization, and sterilization to maintain product integrity and safety.

Pasteurization and Sterilization

In dairy processing, milk and products are heated to eliminate pathogens. Plate heat exchangers excel in efficiency and compactness for pasteurization, providing uniform heating to ensure safety and quality.

For UHT sterilization, heat exchangers deliver high temperatures briefly to extend shelf life without compromising taste.

Heating and Cooling Applications

Controlled heating and cooling are vital for processes like curd formation and product stabilization. Our systems recover energy, reducing costs while maintaining hygiene.

Our heat exchangers withstand dairy environments, resisting acids and temperature variations. They endure rigorous CIP chemicals, upholding sanitation without degradation.

In dairy solutions, heat exchangers are integral, impacting efficiency, cost, and product quality. Their role in thermal management and energy recovery makes them essential.

Precise Temperature Control

Our solutions ensure dairy products are heated or cooled precisely, preserving quality and flavor throughout processing.

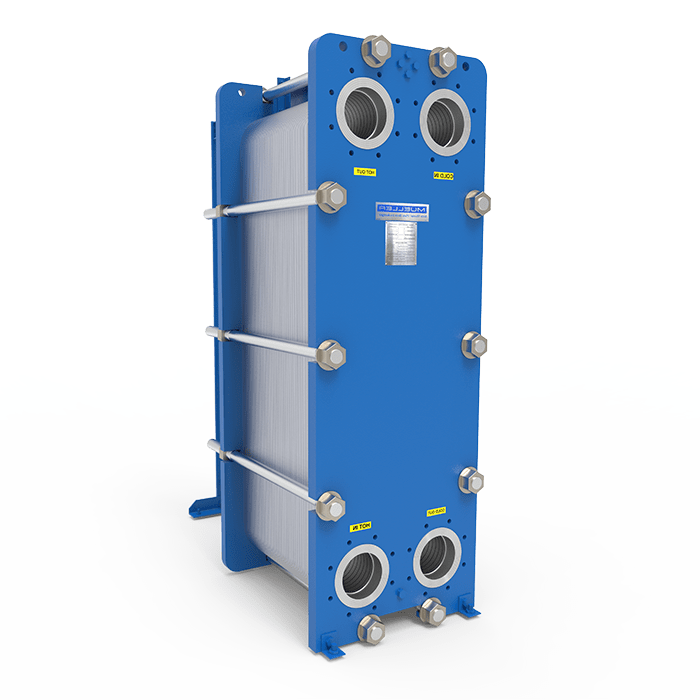

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

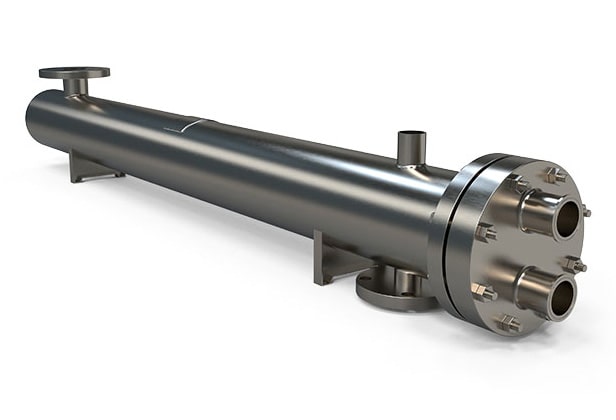

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

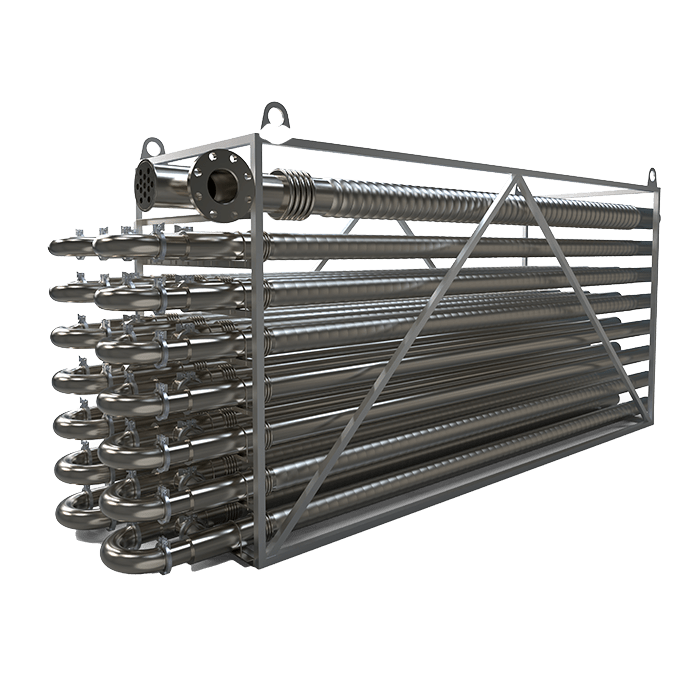

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready