Dairy Heat Exchangers for Dairy Cream

Dairy cream processing requires specialized heat transfer to manage high fat content (18–40%) without causing separation or excessive fouling. Plate-and-frame exchangers provide efficient pasteurization at 72–85°C, shell-and-tube handle viscous flows under pressure, tube-in-tube offer gentle low-shear heating for UHT up to 150°C, and chillers ensure rapid cooling to 4°C, all while complying with FDA, PMO, and 3-A standards to preserve emulsion stability and product quality.

Applications

- Cream Pre-Heating: Heat exchangers warm separated cream from 4°C to 50–60°C regeneratively, preparing for pasteurization while recovering energy from outgoing streams.

- HTST Pasteurization: Systems heat cream to 72–85°C for 15–20 seconds, eliminating pathogens like Listeria while minimizing heat damage to fat globules in table or whipping cream.

- UHT Sterilization: Tubular exchangers process cream at 135–150°C for extended shelf life, enabling aseptic packaging without refrigeration while preventing scorching.

- Rapid Cooling: Integrated chillers drop pasteurized cream to 4°C in seconds using glycol loops, preventing bacterial growth and maintaining smooth consistency.

- CIP Cleaning: Automated cycles with alkaline and acid solutions remove fat residues and proteins, restoring thermal efficiency in high-fouling cream lines.

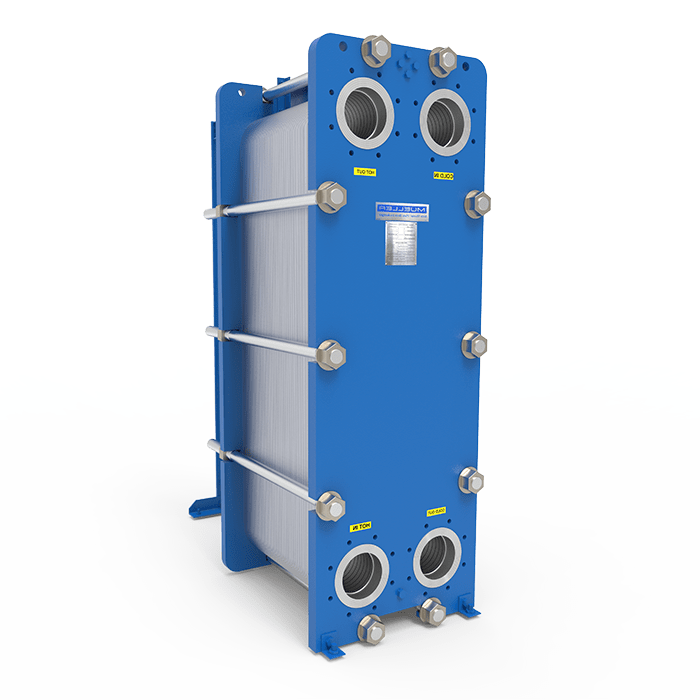

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

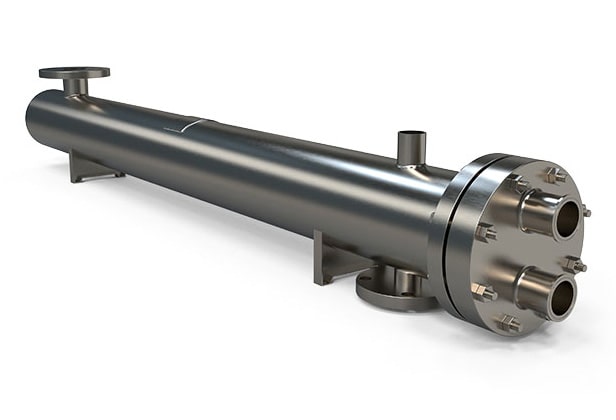

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

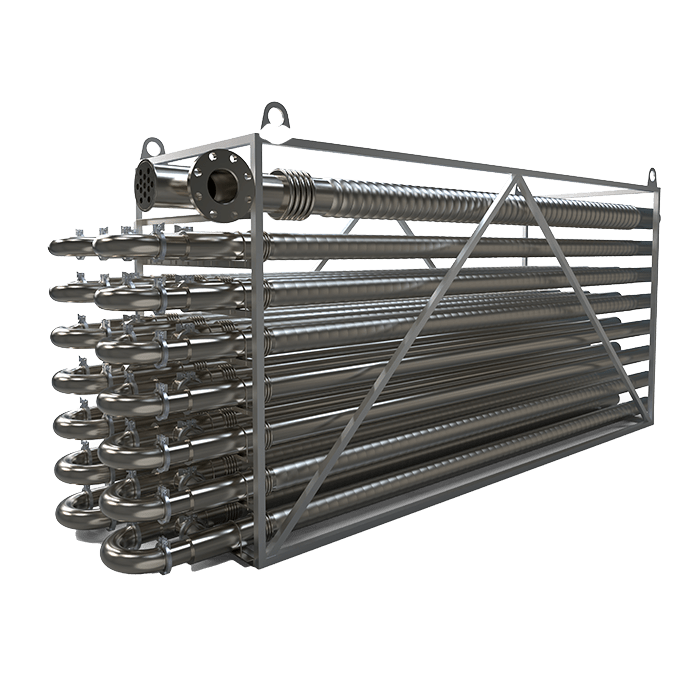

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Dairy Cream

Dairy cream processing benefits greatly from specialized heat exchangers that accommodate its high fat content and viscosity. A premium cream producer minimized separation issues by 70% after implementing shell-and-tube exchangers for robust pasteurization at 85°C and advantage chillers for precise cooling, reducing waste by 25% and ensuring consistent quality across batches for over a year.

These exchangers feature 316L stainless steel with wide channels to handle cream's flow characteristics, FDA-approved materials to avoid contamination, and regenerative designs that recover up to 92% of heat energy. Tube-in-tube options provide gentle processing to preserve emulsion, while plate-and-frame units offer compact efficiency for smaller lines. Integrated PLC controls monitor temperature differentials in real-time for optimal safety and efficiency.

From artisanal dairies to industrial cream suppliers, these heat exchangers enable safe pasteurization, extended shelf life through UHT, and reliable cooling—delivering dairy cream with superior whipability, flavor, and microbial safety for culinary and retail applications.