Dairy Heat Exchangers for Cheese Processing

Cheese making involves precise heating for coagulation, cooking curds, and cooling for maturation while managing whey by-products. Plate-and-frame exchangers pasteurize milk at 72°C, shell-and-tube cook curds at 30–55°C, tube-in-tube gently heat whey, and Advantage chillers cool brines or final wheels to 4–12°C—all minimizing protein fouling and ensuring 3-A compliance for consistent yield and quality.

Applications

- Milk Pasteurization: Heat exchangers pasteurize cheese milk at 72°C for 15 seconds, preparing for rennet addition without damaging caseins.

- Curd Cooking: Controlled heating raises curd-whey mixture to 38–55°C, expelling moisture for firm texture in hard cheeses like cheddar.

- Whey Processing: Systems heat or cool separated whey for further concentration, recovering value in by-products.

- Brine Cooling: Chillers maintain brine at 4–12°C for salting cheeses like mozzarella, ensuring even absorption and safety.

- CIP for Casein Fouling: Automated CIP removes curd residues and minerals, using acid washes to restore efficiency in cheese vats and lines.

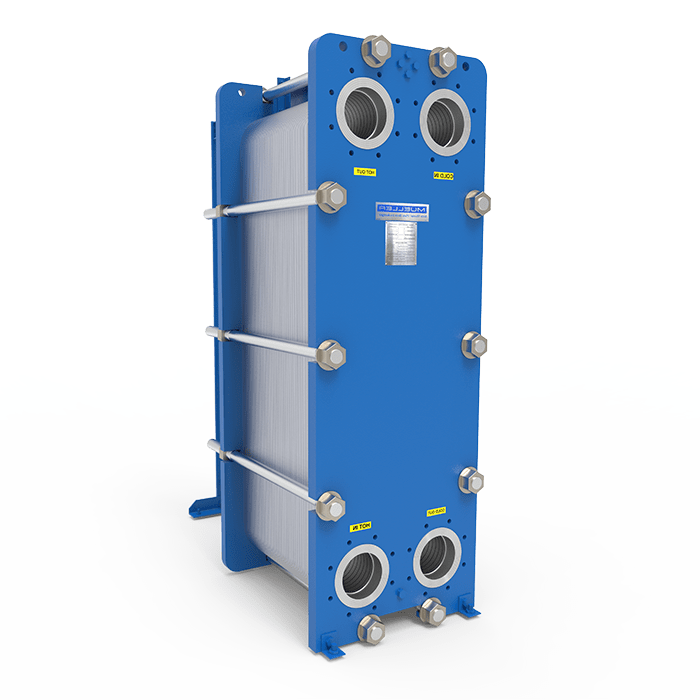

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

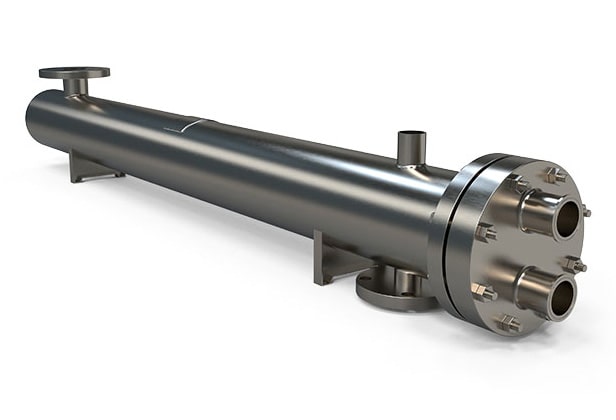

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

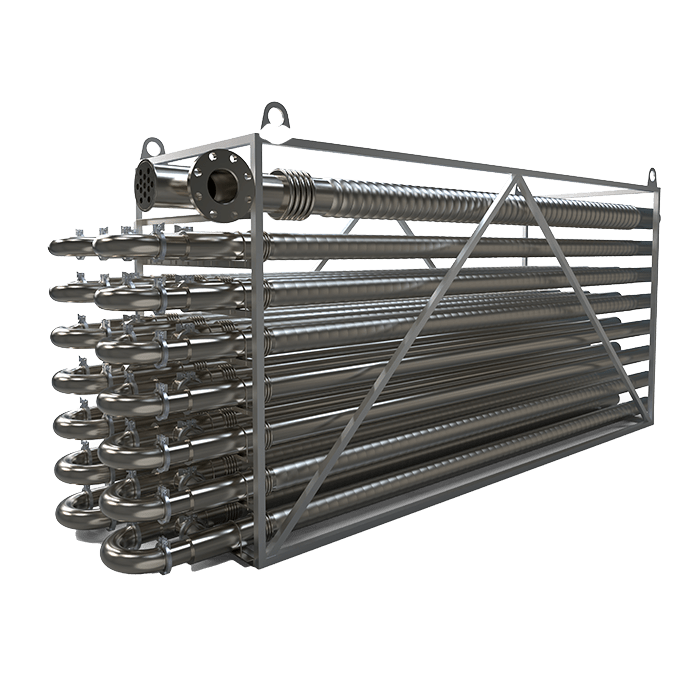

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Cheese Processing

Cheese quality hinges on precise thermal steps from coagulation to maturation. A cheddar producer increased yield by 15% using shell-and-tube for curd cooking and Advantage chillers for brine cooling, with plate-and-frame pasteurizers—reducing whey loss, improving texture uniformity, and passing all safety audits with zero recalls over two years.

These exchangers use corrosion-resistant 316L stainless, wide-gap designs for curds, and regenerative recovery to optimize energy during cooking. Tube-in-tube systems gently process whey without shearing, while PLC integration controls temperature ramps for specific cheese types. Robust CIP handles casein and mineral fouling effectively.

From fresh mozzarella to aged parmesan, these heat exchangers deliver controlled pasteurization, curd cooking, whey management, and cooling—producing cheeses with ideal moisture, flavor profile, and safety for artisanal and industrial scales.