Dairy Heat Exchangers for Creams and Concentrates

Processing creams and concentrates demands gentle yet efficient heat transfer to manage high fat content, prevent emulsion breakdown, and achieve desired solids levels. Dairy heat exchangers, such as plate-and-frame for efficient pasteurization, shell-and-tube for robust handling of viscous streams, tube-in-tube for low-shear applications, and chillers for precise cooling, enable HTST or UHT treatments up to 150°C followed by rapid chilling to 4°C, complying with FDA, PMO, and 3-A standards while reducing fouling from proteins and fats.

Applications

- Cream Pasteurization: Heat exchangers heat cream to 72–85°C for HTST, killing pathogens while preserving fat globules and texture in whipping or heavy cream products.

- Concentration Evaporation: Multi-effect falling film systems concentrate skim milk or whey to 50%+ solids at 50–70°C under vacuum, minimizing caramelization and energy use.

- Regenerative Cooling: Post-processing cooling drops concentrates to 4–10°C using glycol chillers, preventing crystallization and ensuring stability during storage.

- UHT for Extended Shelf Life: Tubular exchangers sterilize cream at 135–150°C for aseptic packaging, enabling ambient storage without separation.

- CIP for Viscous Residues: Automated clean-in-place cycles remove fat and protein buildup, restoring efficiency in high-fouling cream and concentrate lines.

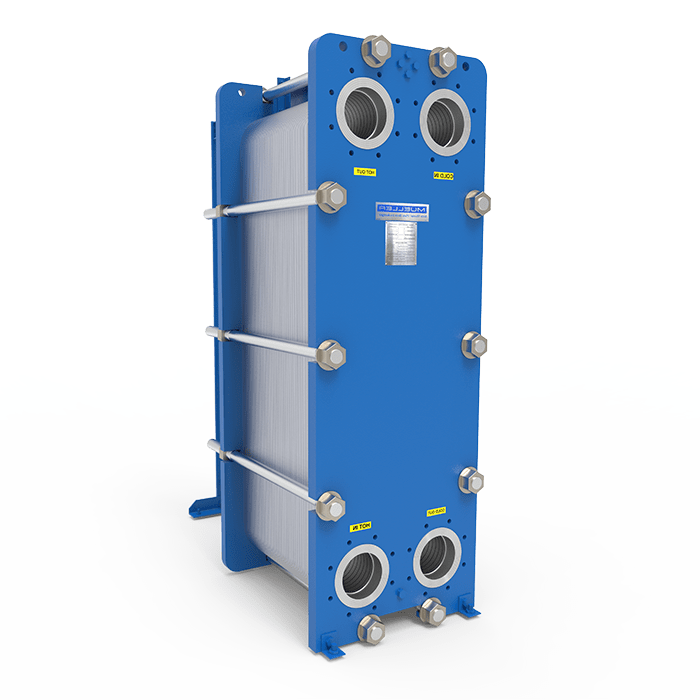

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

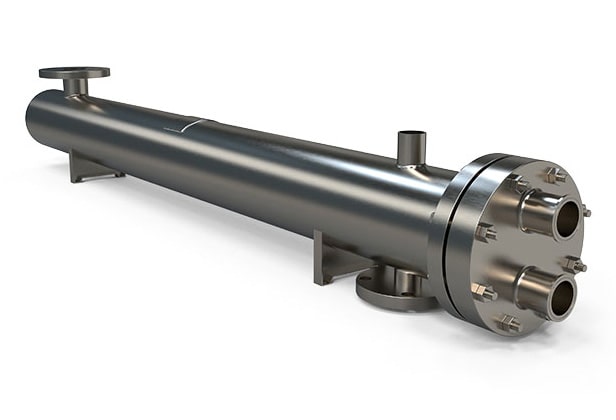

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

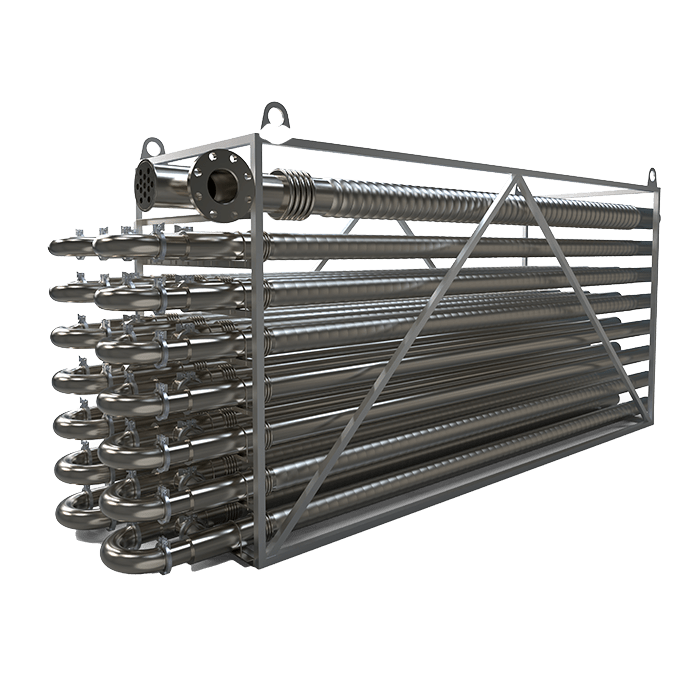

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Creams and Concentrates

In creams and concentrates processing, specialized heat exchangers are crucial for handling high-fat emulsions and high-solids streams without compromising product integrity. A dairy processor specializing in whipping cream reduced fouling downtime by 65% after adopting tube-in-tube exchangers with gentle flow paths and integrated CIP, achieving consistent pasteurization at 85°C, cutting maintenance costs by 30%, and maintaining zero quality defects over 18 months.

These systems utilize 316L stainless steel with polished surfaces, wide-channel designs for viscous flows, and FDA-compliant seals to prevent contamination. Regenerative configurations recover up to 90% of heat in evaporation processes, while chillers provide tight temperature control for cooling to prevent phase separation. SCADA-integrated PLCs offer real-time viscosity monitoring and automated adjustments for optimal performance.

From boutique creameries to large-scale concentrate producers, these heat exchangers ensure efficient pasteurization, concentration, and cooling—delivering superior texture, flavor stability, and compliance for premium dairy products.