Dairy Heat Exchangers for Recombined Milk Processing

Recombined milk production requires controlled heating to fully hydrate milk powder, emulsify added fats, and achieve sterilization without phase separation. Tubular and plate heat exchangers with direct steam injection or regenerative preheat raise reconstituted milk to 135–150°C for UHT, followed by flash cooling and aseptic homogenization—ensuring 6+ month ambient stability and fresh milk taste.

Applications

- Powder Hydration & Preheating: Dry milk solids are mixed with water and preheated to 60–70°C in tubular exchangers to dissolve proteins and prevent clumping before fat addition.

- UHT Sterilization: Reconstituted blend is heated to 140°C for 4 seconds via direct steam infusion or indirect tubular systems, eliminating spores while preserving nutritional profile.

- Flash Cooling & Homogenization: Sterilized product is flash-cooled to 70–75°C for downstream aseptic homogenization, ensuring stable fat emulsion and smooth mouthfeel.

- CIP with Powder Residue Removal: High-velocity CIP with caustic, acid, and enzymatic stages removes protein-fat films and powder buildup, restoring efficiency in high-throughput lines.

- Energy Recovery Systems: Regenerative heat exchange between incoming mix and outgoing UHT product recovers up to 90% of energy, reducing steam and cooling water demand.

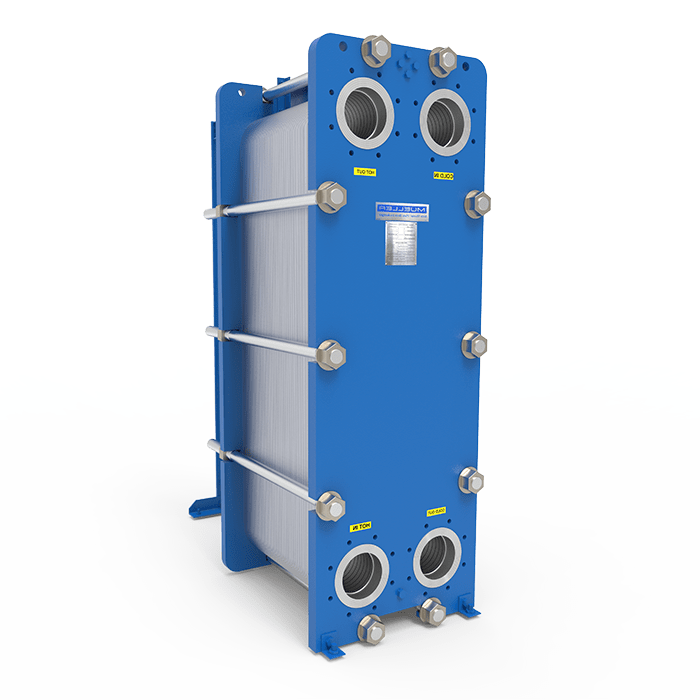

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

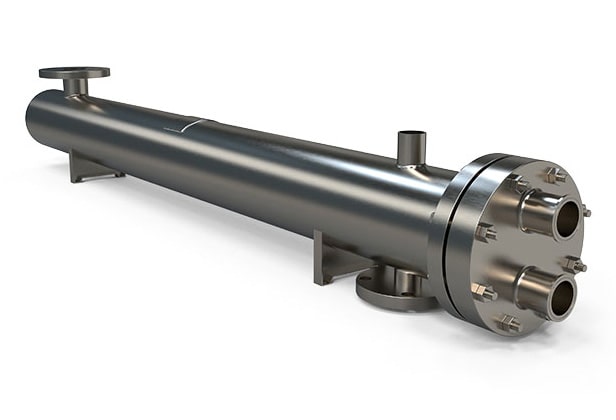

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

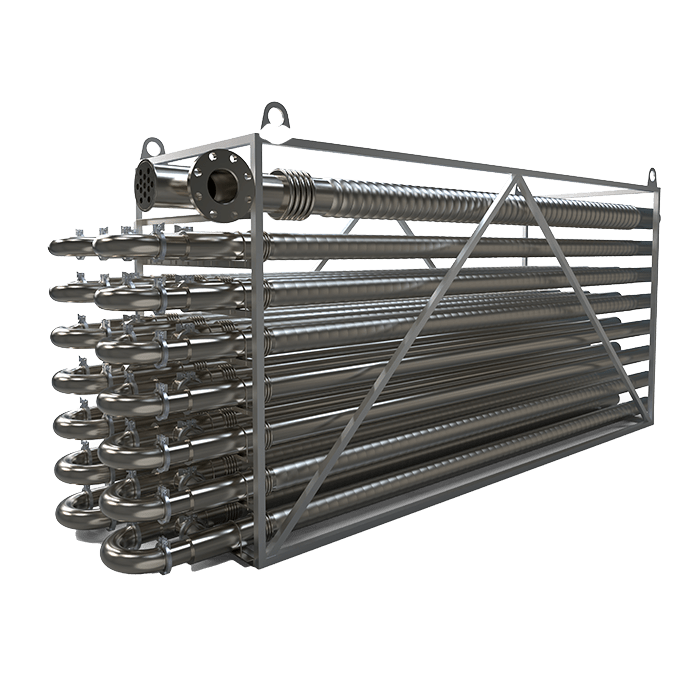

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Recombined Milk Processing

Recombined milk enables year-round production in regions with limited fresh milk access, but requires precise thermal control to match fresh milk quality. A Southeast Asian processor achieved 99.7% first-pass acceptance after installing a UHT tubular system with direct steam injection and regenerative preheat. The upgrade reduced powder burn-on by 80%, cut energy use by 45%, and delivered ambient-stable recombined milk indistinguishable from fresh in blind taste tests.

These heat exchangers feature corrugated or multi-tube designs to handle high powder loads and fat emulsions without fouling. 316L stainless construction with sanitary welds, aseptic barriers, and CIP-optimized flow paths ensure sterility. PLC integration with inline density and viscosity sensors enables real-time composition control, while flash vessels and vacuum deodorization remove off-flavors from reconstituted fats.

From small-scale regional plants to multinational UHT milk producers, our systems deliver reliable powder hydration, sterile processing, and energy-efficient operation—ensuring every carton of recombined milk meets global standards for safety, taste, and shelf life.