Dairy Heat Exchangers for Lactose-Free Milk Processing

Lactose-free milk requires gentle, controlled heating to activate lactase enzyme without degrading taste or nutrients. Plate-and-frame heat exchangers with precise temperature zones heat milk to 40–55°C for enzyme incubation, followed by HTST pasteurization at 72°C and rapid cooling to 4°C—ensuring 100% lactose hydrolysis, FDA compliance, and premium shelf-stable quality.

Applications

- Enzyme Incubation Heating: Milk is gently warmed to 40–45°C in regenerative sections, enabling optimal lactase activity to convert >99.9% of lactose into glucose and galactose.

- HTST Pasteurization: Post-incubation, milk is heated to 72°C for 15 seconds in dedicated plate sections, inactivating enzymes and pathogens while preserving natural sweetness.

- Regenerative & Final Cooling: Heat is recovered to pre-warm incoming milk, then cooled to 4°C using chilled glycol, preventing microbial growth and ensuring 21+ day refrigerated life.

- CIP with Enzyme Residue Removal: Automated CIP cycles include enzyme-specific detergents to eliminate protein and sugar buildup, restoring full heat transfer efficiency.

- Homogenization Temperature Control: Consistent 55–60°C inlet to homogenizers ensures uniform fat dispersion in lactose-free whole and reduced-fat variants.

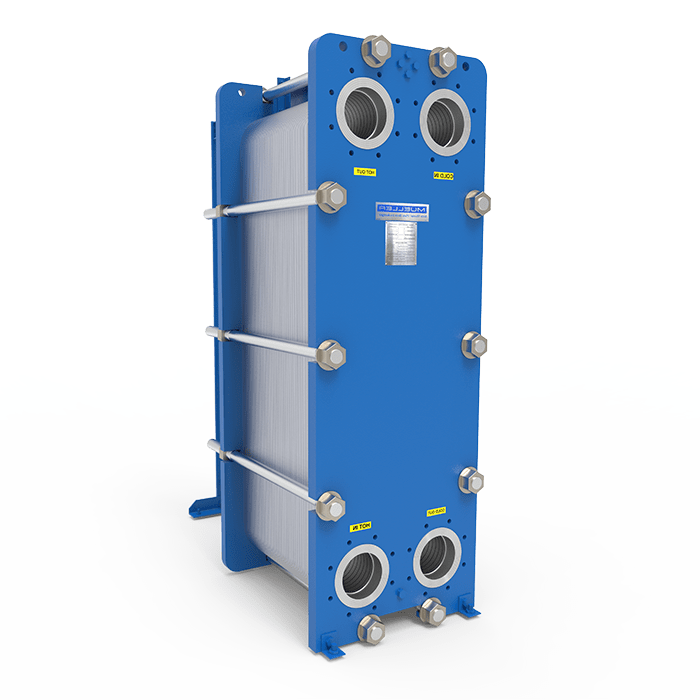

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

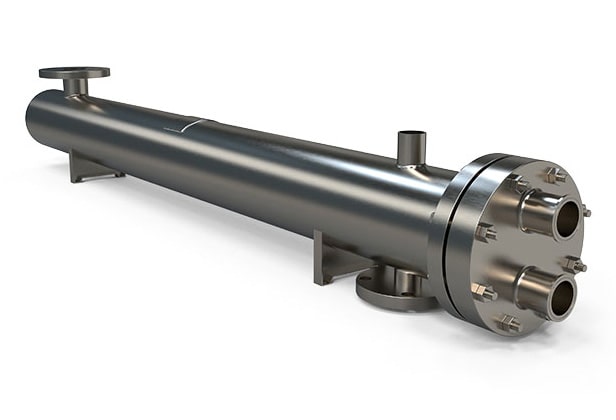

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

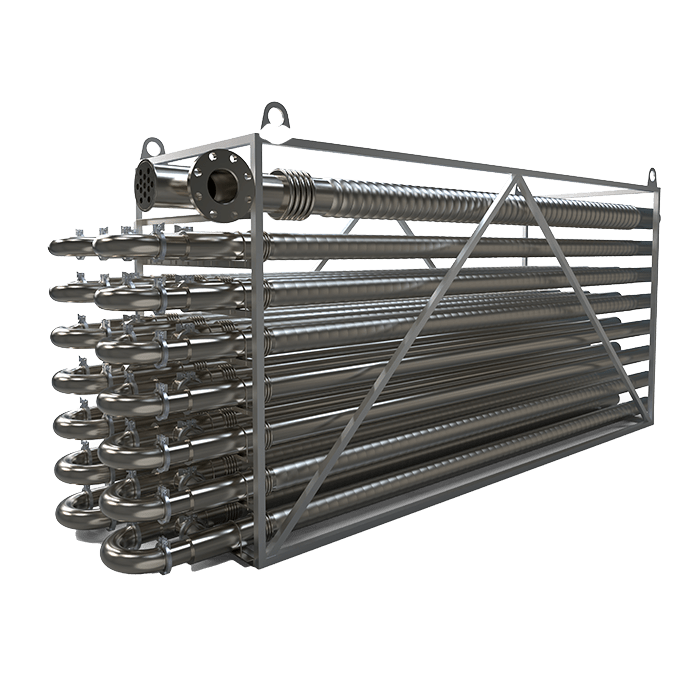

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Lactose-Free Milk Processing

Lactose-free milk demands exact thermal control to activate enzymes without compromising taste or shelf life. A leading dairy brand increased production capacity by 35% after installing a multi-zone plate heat exchanger with dedicated enzyme incubation and pasteurization sections. The system achieved 100% lactose conversion, reduced energy use by 38%, and maintained zero off-flavor incidents over 18 months of continuous operation.

These heat exchangers feature 316L stainless steel with electropolished surfaces, FDA-approved EPDM gaskets, and segregated flow paths to prevent cross-contamination between raw and treated milk. PLC automation ensures precise dwell times at 42°C for lactase activity and 72°C for pathogen kill, with real-time lactose residual monitoring via inline sensors. Full CIP with enzyme-specific cleaning agents restores performance in under 60 minutes.

From regional dairies to global lactose-free brands, our systems deliver consistent enzyme activation, gentle pasteurization, and rapid cooling—ensuring every liter of lactose-free milk is safe, naturally sweet, and ready for premium market positioning.