Dairy Heat Exchangers for Milk Processing

In milk processing, precise heat transfer is essential to eliminate pathogens, preserve nutritional value, and achieve desired product consistency. Dairy heat exchangers, including plate-and-frame, shell-and-tube, and tube-in-tube designs, deliver efficient heating to 72°C for HTST pasteurization or 135°C for UHT, followed by rapid cooling to 4°C, ensuring compliance with FDA, PMO, and 3-A standards while minimizing fouling from milk proteins and fats.

Applications

- Raw Milk Pre-Heating: Heat exchangers warm incoming milk from 4°C to 40–50°C using regenerative sections, recovering heat from pasteurized milk to boost energy efficiency by up to 95% in large-scale processing.

- Pasteurization (HTST): Plate heat exchangers achieve 72°C for 15 seconds, killing Listeria and Salmonella while retaining 99% of vitamins, supporting daily output of 100,000+ liters in fluid milk plants.

- Cooling After Pasteurization: Integrated cooling sections drop milk to 4°C in seconds using chilled water or glycol loops, preventing bacterial regrowth and extending shelf life to 21 days.

- UHT Sterilization: Tubular heat exchangers handle 135–150°C for 2–5 seconds, enabling aseptic packaging for ambient-stable milk with 6-month shelf life without refrigeration.

- Evaporation for Condensed Milk: Multi-effect falling film evaporators concentrate milk to 40–50% solids at low temperatures (50–70°C), preserving flavor and reducing energy use by 70%.

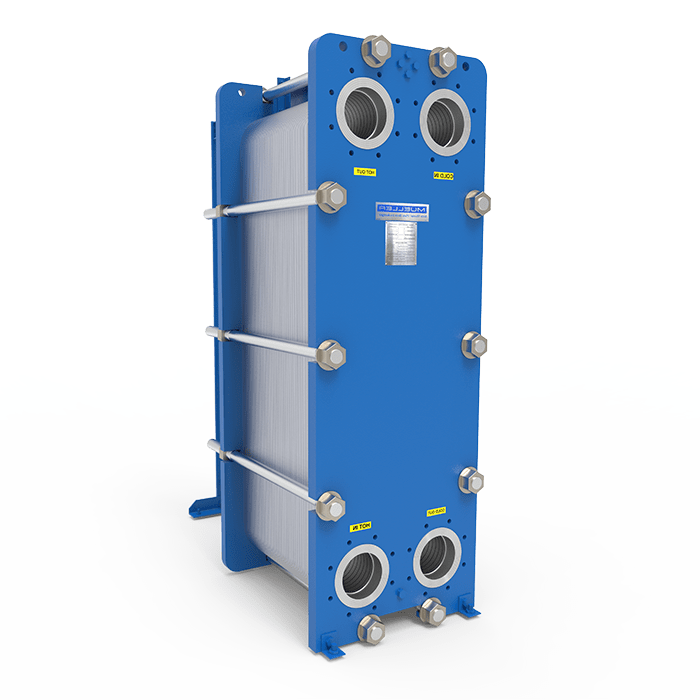

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

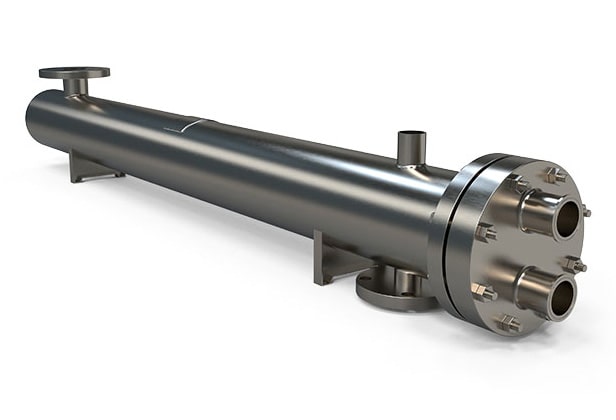

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

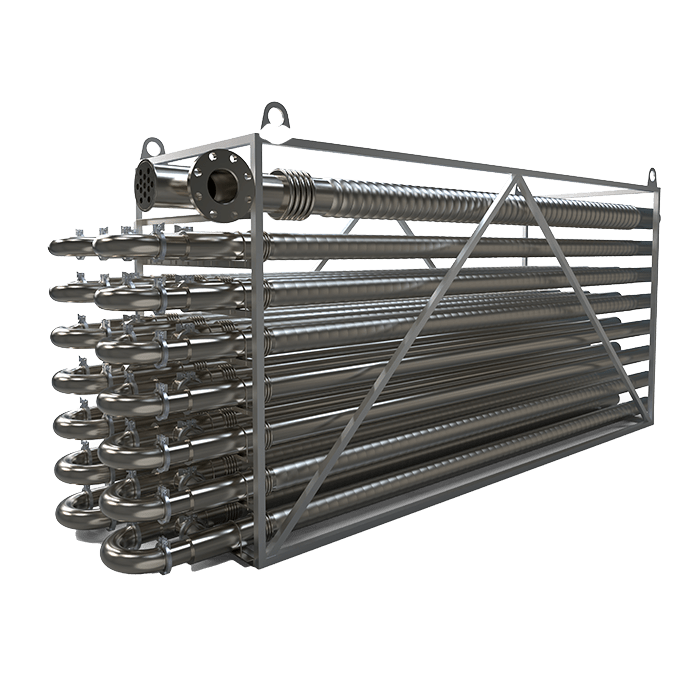

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Milk Processing

In milk processing, reliable heat exchangers are vital for food safety and operational efficiency. A mid-sized dairy cooperative faced $500K in losses from Listeria outbreaks linked to inadequate pasteurization hold times. After upgrading to multi-section plate heat exchangers with automated temperature controls and integrated CIP, they achieved 99.99% pathogen reduction, cut energy costs by 40%, and passed all PMO inspections for over two years with zero recalls.

Dairy heat exchangers feature electropolished 316L stainless steel surfaces, crevice-free welds, and EPDM gaskets compliant with FDA and 3-A standards. Regenerative designs recover up to 95% of heat, while scraped-surface options handle viscous flows without fouling. PLC integration with SCADA systems provides real-time monitoring, alarm notifications, and data logging for HACCP compliance.

From farm-level reception to high-volume bottling lines, these systems support white milk, lactose-free, condensed, and recombined varieties—delivering consistent quality, reduced waste, and scalable performance for processors of all sizes.