3-A Compliance in Dairy Heat Exchangers

3-A Sanitary Standards represent the highest benchmark for hygienic equipment design in dairy processing. Our heat exchangers carry the official 3-A symbol through rigorous third-party verification, confirming that every product-contact surface is cleanable to a microbiological level, fully drainable, and constructed without crevices or dead legs. This certification is not optional—it is mandatory for processors who demand zero risk of contamination.

Key 3-A Compliance Features

- Official 3-A Symbol Authorization: All dairy exchangers are third-party verified and carry the 3-A symbol per standards 08-17 (shell & tube), 11-09 (plate), and 35-04 (tubular).

- Product Contact Surfaces: 316L stainless steel with Ra = 32 µin (0.8 µm) electropolished finish on all wetted surfaces for rapid drainage and cleanability.

- No Threads Eliminated: No threads in product zone; only sanitary Tri-Clamp, weld, or compression fittings allowed.

- Full Drainability: Horizontal installation with sloped tubes and self-venting designs ensure complete drainage—no product retention.

- Leak Protection: Double tubesheets and leak-detect ports on shell & tube; clip-on gaskets with metal stops on plate exchangers.

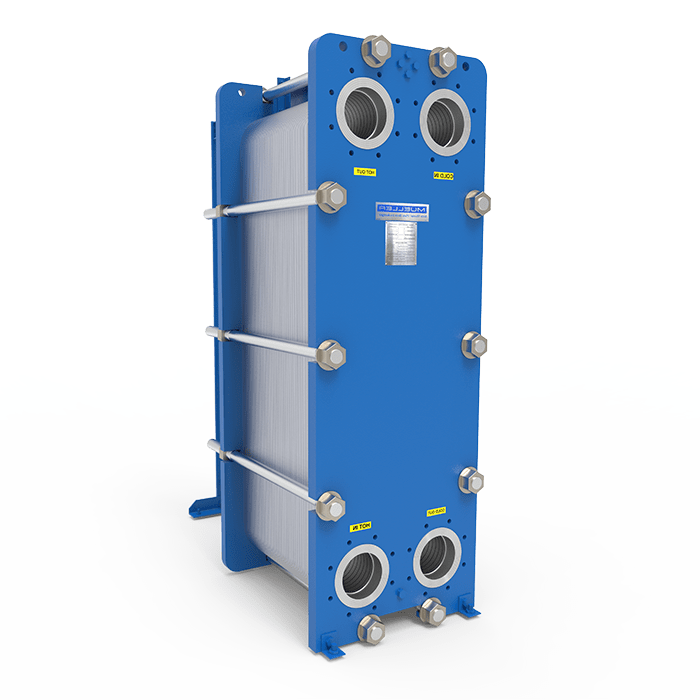

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

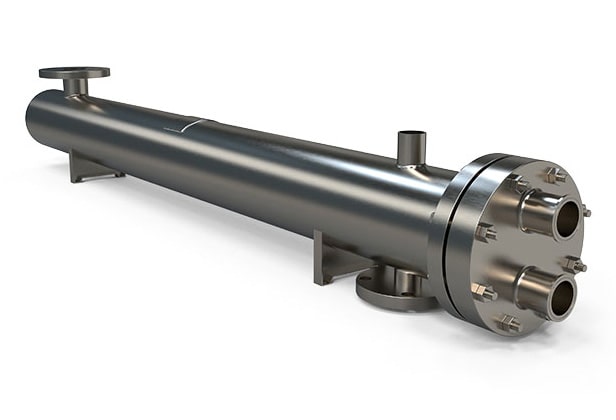

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

The Importance of 3-A Compliance in Dairy Heat Exchangers

3-A compliance is not just a certification—it's a commitment to food safety and equipment performance. A major dairy cooperative eliminated recurring Listeria issues after switching to our 3-A certified exchangers, achieving perfect audit scores and extending production runs by 50%. The 3-A symbol guarantees that every surface is cleanable to a microbiological level, fully inspectable, and constructed with approved materials.

Our exchangers undergo independent third-party verification to carry the official 3-A symbol, meeting specific standards for shell & tube (08-17), plate (11-09), and tubular (35-04) designs. This includes orbital welding, polished surfaces, and documented drainability testing. We provide complete 3-A documentation packages with every unit, including material certificates, surface finish reports, and weld logs.

From small artisanal producers to the largest dairy processors, 3-A compliance with our heat exchangers ensures regulatory confidence, reduced risk of recalls, and superior cleanability—protecting your brand and your customers, year after year.