Dairy Heat Exchangers for Dairy Permeate Processing

Dairy permeate processing involves handling the lactose-rich filtrate from milk or whey ultrafiltration, requiring gentle heat transfer to pasteurize without caramelization and concentrate efficiently. Plate-and-frame exchangers pasteurize at 72–75°C, shell-and-tube manage multi-effect evaporation to 50–60% solids, tube-in-tube provide low-shear cooling, and Advantage chillers cool to 4–10°C for storage or drying—all while minimizing lactose fouling and ensuring 3-A compliance.

Applications

- Permeate Pasteurization: Heat exchangers pasteurize fresh permeate at 72–75°C to control microbes while preserving lactose and minerals for food ingredient use.

- Pre-Evaporation Heating: Regenerative warming to 50–60°C prepares permeate for concentration, recovering energy from condensate streams.

- Multi-Effect Evaporation: Systems concentrate permeate to 50–60% solids under vacuum at low temperatures, preventing Maillard reactions.

- Post-Concentration Cooling: Chillers rapidly cool concentrated permeate to 10–15°C to inhibit crystallization before spray drying or storage.

- CIP for Lactose Fouling: Automated CIP removes mineral and lactose deposits using acid washes, maintaining efficiency in permeate processing lines.

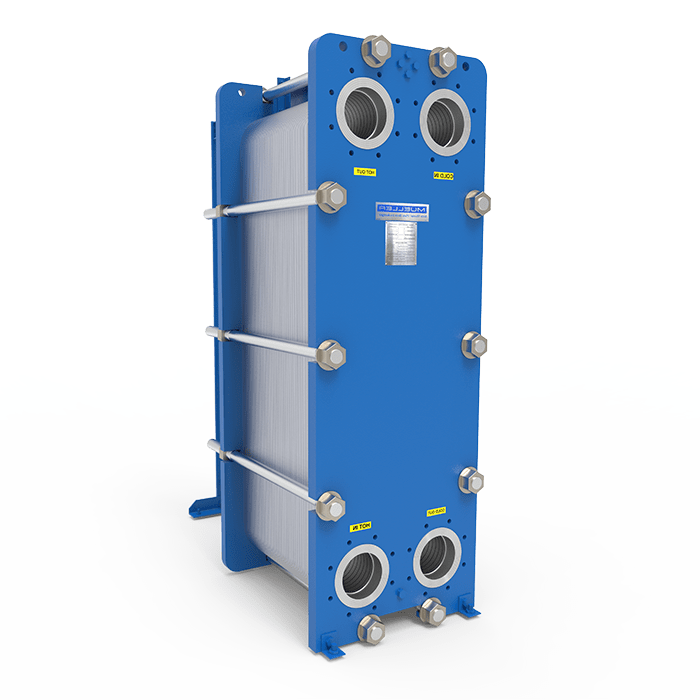

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

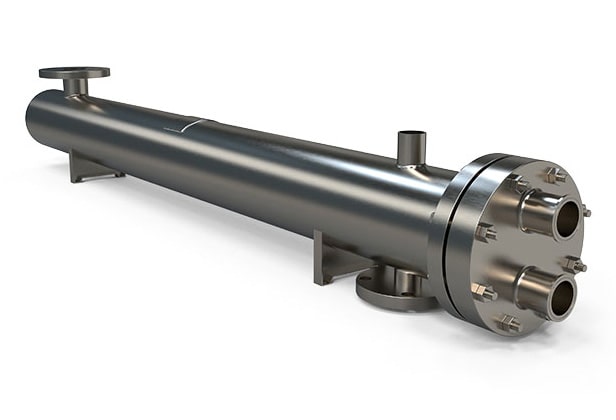

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

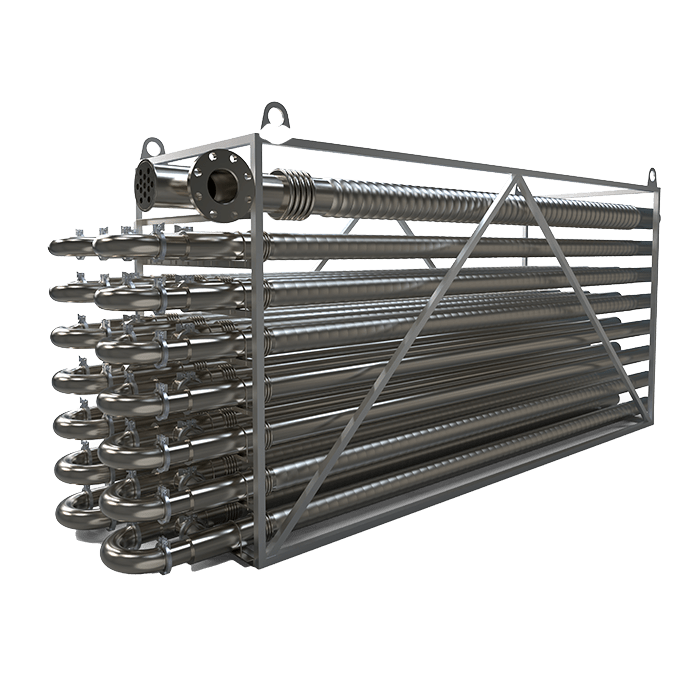

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Dairy Permeate Processing

Dairy permeate, a valuable by-product rich in lactose and minerals, benefits from optimized thermal processing to maximize usability in beverages and animal feed. A whey processing facility increased permeate concentration efficiency by 30% using multi-effect shell-and-tube evaporators and regenerative plate exchangers, with Advantage chillers for final cooling—reducing energy costs by 40% and achieving consistent 55% solids with no crystallization issues over 12 months.

These exchangers feature mineral-tolerant designs with smooth surfaces to resist scaling, 316L stainless steel, and vacuum-compatible construction for low-temperature evaporation. Tube-in-tube systems provide gentle handling to prevent lactose degradation, while PLC controls monitor solids content in real-time. Specialized CIP with acid descaling ensures long run times in high-mineral environments.

From cheese manufacturing by-product streams to standalone permeate plants, these heat exchangers deliver effective pasteurization, energy-efficient concentration, and controlled cooling—producing high-quality dairy permeate for cost-effective ingredient applications and sustainable dairy operations.