Dairy Heat Exchangers for Fermented Dairy Products

Fermented dairy production requires accurate temperature control to promote beneficial bacteria while preventing spoilage. Dairy heat exchangers, including plate-and-frame for rapid pasteurization, shell-and-tube for robust curd heating, tube-in-tube for gentle incubation, and chillers for precise cooling, enable HTST treatments at 85–95°C followed by controlled fermentation at 40–45°C and chilling to 4°C, complying with FDA, PMO, and 3-A standards while managing acidification-induced fouling.

Applications

- Milk Pasteurization: Heat exchangers pasteurize milk at 72–85°C for starter culture addition, ensuring safety before fermentation begins.

- Incubation Heating: Gentle warming maintains 40–45°C for yogurt or 30–35°C for cheese curd formation, promoting lactic acid production.

- Curd Cooking: Controlled heating cooks cheese curd to expel whey, achieving desired firmness without overcooking.

- Post-Fermentation Cooling: Chillers rapidly cool products to 4–10°C to halt fermentation, set texture, and extend shelf life.

- CIP for Acidic Fouling: Automated clean-in-place removes lactic acid and protein residues, restoring efficiency in fermented dairy lines.

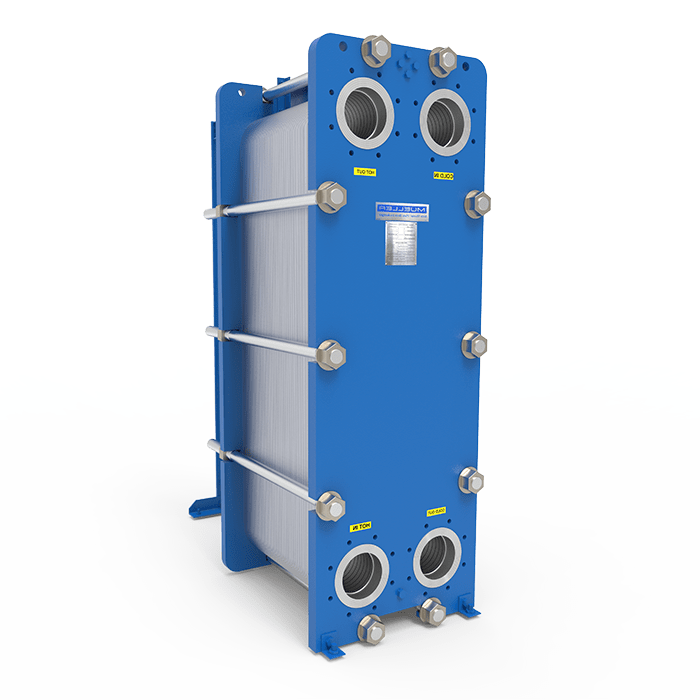

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

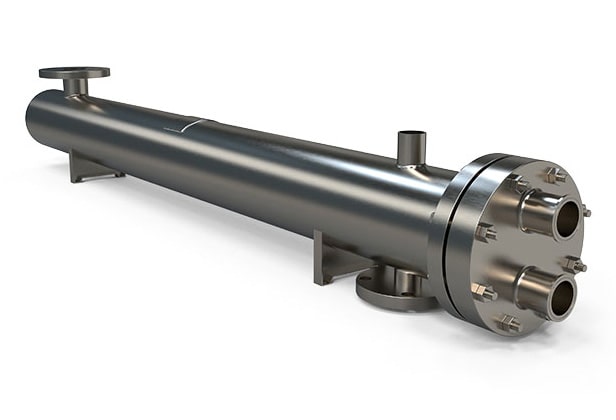

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

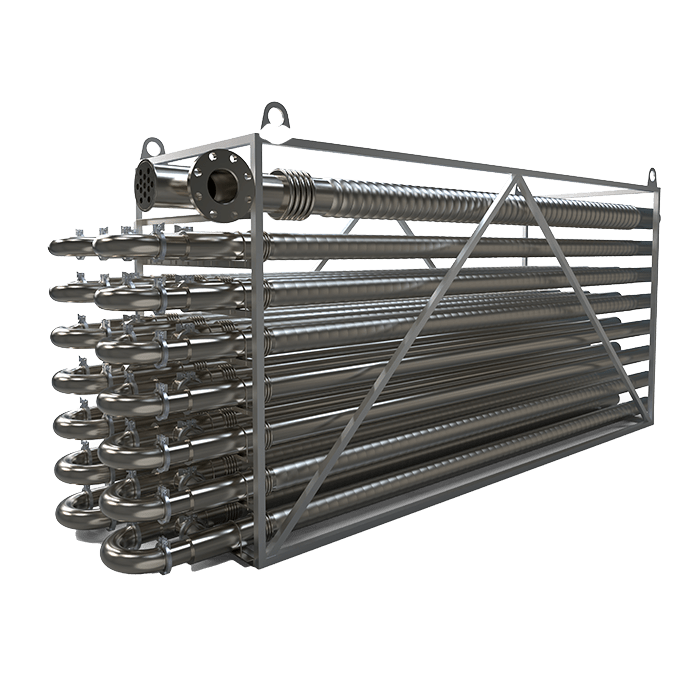

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Fermented Dairy Processing

Fermented dairy products like yogurt and cheese rely on precise temperature management for successful culturing. A yogurt manufacturer reduced fermentation time by 20% using tube-in-tube exchangers for gentle incubation heating and plate-and-frame for rapid pasteurization, with Advantage chillers for quick post-fermentation cooling—improving texture uniformity and cutting energy use by 25% with no quality issues over 18 months.

These exchangers feature acid-tolerant 316L stainless steel, wide channels for viscous curds, and regenerative designs to maintain stable fermentation temperatures. Shell-and-tube units handle high-pressure curd cooking, while PLC systems monitor pH and temperature for automated control. CIP protocols with enzyme cleaners effectively remove acidic residues.

From small artisanal cheese makers to large yogurt plants, these heat exchangers provide safe pasteurization, controlled fermentation, and efficient cooling—producing fermented dairy with balanced acidity, firm texture, and extended shelf life for consumer favorites.