Tube-in-Tube Heat Exchangers for Dairy

Sensitive dairy products with particulates require careful handling to avoid damage. Our tube-in-tube designs feature coaxial tubes with annular flow in polished 316L stainless to provide uniform, low-shear heating/cooling while allowing full CIP circulation—perfect for fruit-filled yogurts and soft cheese processing.

Applications

- Fruit Yogurt Processing: Tube-in-tube exchangers gently heat yogurt base with fruit pieces to 85°C, preserving chunk integrity during pasteurization.

- Soft Cheese Production: Coaxial design cooks delicate curds at 32–38°C without shearing, maintaining texture in cream cheese lines.

- Cottage Cheese Cooling: Gentle cooling of curd and cream mixture to 4°C prevents clumping in 10,000 L/h systems.

- Particulate Whey Handling: Systems process whey with protein aggregates at low shear, recovering value for supplements.

- CIP Circulation: Annular flow paths allow high-velocity cleaning solutions, ensuring thorough sanitation without dead zones.

Sanitary Design

Hygienic Standards for Dairy Processing

- Electropolished 316L Surfaces

- Crevice-Free Orbital Welds

- Full Drainability & CIP Optimization

3-A Compliance

Certified for Dairy Safety

- Official 3-A Symbol Authorized

- Ra = 32 µin Product Surfaces

- No Threads in Wetted Areas

The Benefits of Tube-in-Tube Heat Exchangers for Dairy

In particulate dairy processing, product integrity is paramount to maintaining texture and quality in products like fruit yogurts and soft cheeses. A fruit yogurt manufacturer reduced fruit damage by 50% using our tube-in-tube exchangers with smooth annular flow, processing 5,000 L/h at low shear while cutting CIP time 40% via full-bore design—meeting FDA standards with zero complaints. This coaxial configuration, featuring a single inner tube within an outer shell, allows for efficient heat transfer while handling solids in suspension, such as fruit pieces or curd particles, without clogging or degradation.

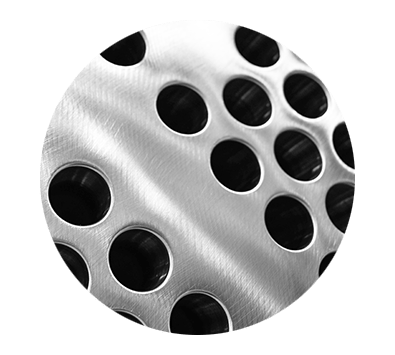

Our tube-in-tube exchangers feature double-tube construction for reliable leak detection and prevention of cross-contamination, 316L electropolished inner tubes for superior hygiene, and sanitary fittings like Tri-Clamp for complete drainability. The coaxial design minimizes pressure drop in viscous flows, while modular sections allow custom lengths to fit specific plant layouts. Options include corrugated or dimpled inner tubes to enhance turbulence and heat transfer for high-viscosity fluids, and integration with particle sensors for real-time monitoring of flow characteristics. Built to 3-A sanitary standards, these exchangers use materials like austenitic stainless steel or titanium for corrosion resistance in demanding dairy environments.

From chunk-filled desserts to soft curd cheeses, our tube-in-tube exchangers provide the gentle handling, superior cleanability through self-draining designs, and operational efficiency for specialized dairy operations. With capabilities for high temperatures up to 350°C and pressures to 1000 bar in some models, they excel in pasteurization plants and heat recovery systems, supporting both monotube for solids-laden fluids and multitube configurations for homogeneous streams—batch after batch, year after year.