Dairy Heat Exchangers for Sour Cream Processing

Sour cream production involves pasteurizing cream, cooling for inoculation, controlled warming for fermentation, and final chilling to set texture. Plate-and-frame exchangers efficiently pasteurize at 85–95°C, tube-in-tube provide gentle heating to 20–25°C for culturing, shell-and-tube handle viscous acidified product, and Advantage chillers rapidly cool to 4–10°C to halt fermentation—all minimizing fouling from lactic acid and fats while ensuring 3-A compliance.

Applications

- Cream Pasteurization: Heat exchangers pasteurize base cream at 85–95°C for 15–30 seconds, killing pathogens before cooling for culture addition.

- Post-Pasteurization Cooling: Rapid cooling to 20–25°C using chillers prepares mix for lactic acid bacteria inoculation without premature souring.

- Fermentation Heating: Gentle warming maintains 20–25°C during 12–18 hour incubation, promoting even acidification to pH 4.5–4.6.

- Final Product Cooling: Chillers cool fermented cream to 4–10°C to stop bacterial activity, set firm texture, and extend shelf life.

- CIP for Acidic Residues: Automated CIP removes lactic acid and fat buildup, using acid-tolerant materials to maintain hygiene in sour cream lines.

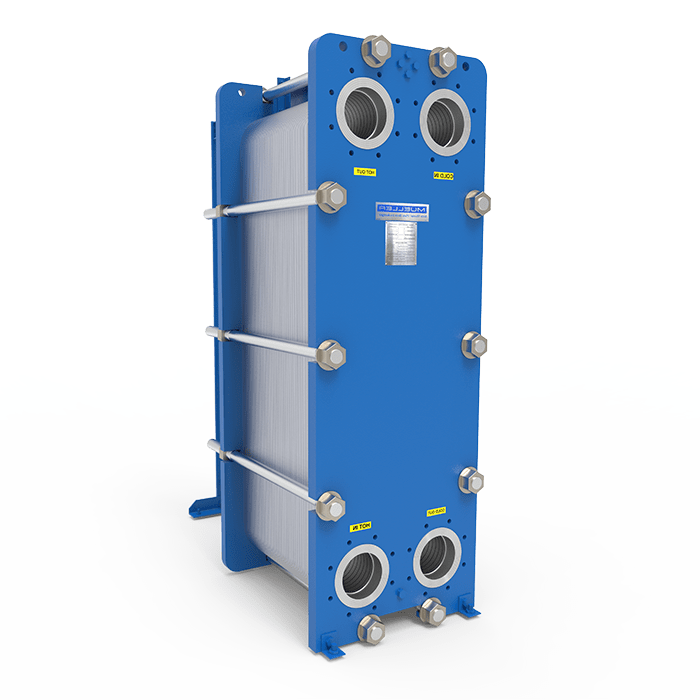

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

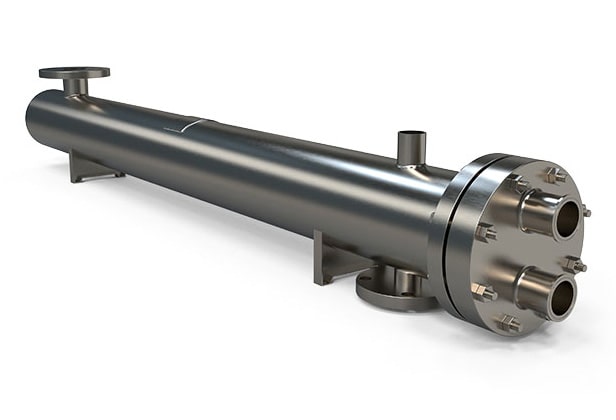

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

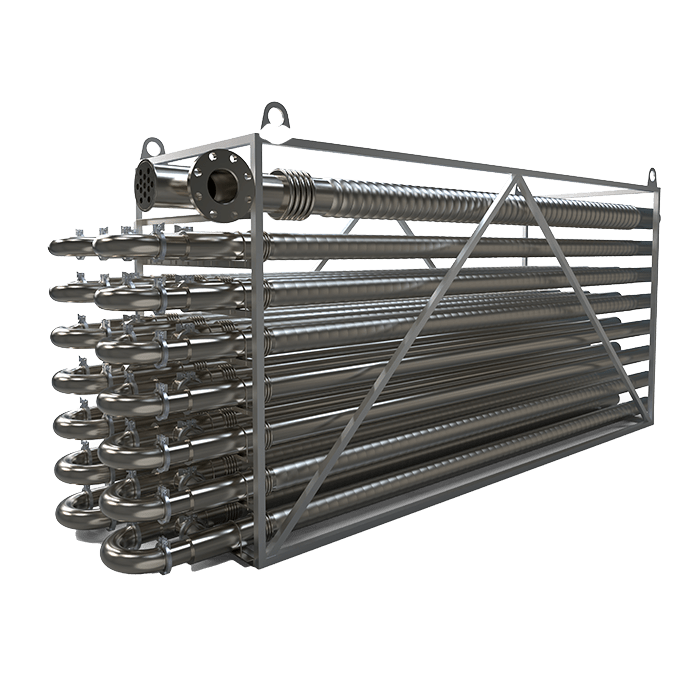

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for Sour Cream Processing

Sour cream's distinctive tang and thickness depend on carefully controlled temperatures during fermentation. A cultured dairy plant improved pH consistency from ±0.3 to ±0.05 by using tube-in-tube exchangers for gentle incubation heating and Advantage chillers for precise post-fermentation cooling, reducing batch variability by 40% and extending shelf life by 7 days with no texture defects over a year.

These exchangers use acid-resistant 316L stainless steel, crevice-free designs, and wide channels to accommodate sour cream's increasing viscosity and acidity. Regenerative heating recovers energy during pasteurization, while PLC controls maintain tight temperature bands during 20–25°C fermentation. CIP systems with specialized detergents effectively remove acidic residues without damaging components.

From small-batch artisanal producers to large-scale sour cream manufacturers, these heat exchangers ensure safe pasteurization, optimal culturing conditions, and rapid cooling—producing sour cream with perfect balance of flavor, firmness, and food safety for dips, toppings, and baking applications.