Sanitary Standards in Dairy Heat Exchangers

Dairy processing demands the highest level of sanitary design to prevent contamination and ensure food safety. Our heat exchangers are built to exceed 3-A Sanitary Standards, featuring electropolished 316L stainless steel with Ra = 0.8 µm (32 µin) surface finish, crevice-free welds, and fully drainable geometries that eliminate dead legs and product hold-up. These design principles, combined with FDA-compliant elastomers and sanitary connections, guarantee rapid, effective CIP and COP while maintaining structural integrity under thermal cycling.

Key Sanitary Features

- 3-A Certified Construction: All product-contact surfaces meet 3-A criteria, including radius corners, sloped drainability, and no threaded connections in wetted areas.

- Electropolished Surfaces: Ra = 0.8 µm finish on tubes and plates to minimize bacterial adhesion and facilitate complete cleaning validation.

- Full Drainability: Horizontal installations with sloped tubes and self-draining designs ensure no residual product remains after production or CIP.

- Leak Detection Systems: Double tubesheets and double-tube designs prevent cross-contamination between product and service fluids.

- CIP-Optimized Flow Paths: High-turbulence designs and smooth transitions enable complete cleaning with minimal chemical usage and shorter cycle times.

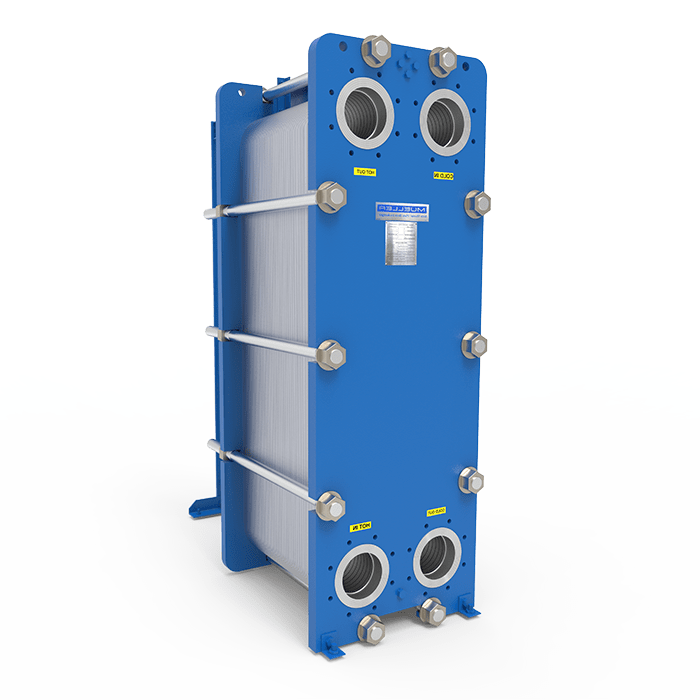

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

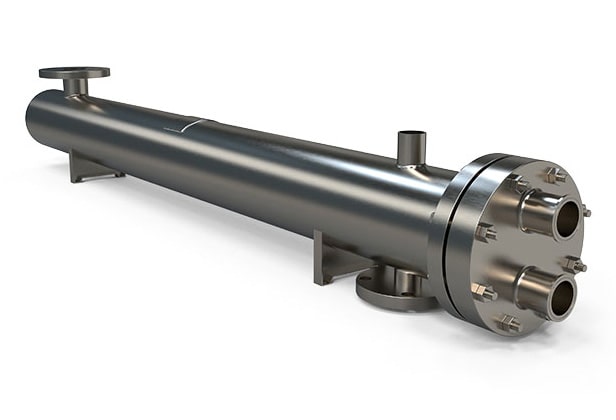

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

Why Sanitary Design Matters in Dairy Heat Exchangers

In dairy processing, even microscopic crevices or poor drainability can harbor pathogens and lead to costly recalls. Our exchangers are built to the strictest sanitary standards from day one, using only FDA-compliant materials, electropolished surfaces, and designs that eliminate dead zones. A major cheese manufacturer achieved 100% CIP effectiveness and zero Listeria detections after upgrading to our 3-A certified systems, extending run times and reducing water/chemical consumption significantly.

Every product-contact surface receives mechanical polishing followed by electropolishing to achieve Ra values = 0.8 µm, dramatically reducing bacterial attachment sites. All welds are orbital and inspected, with no threads or dead legs in wetted areas. Gaskets are FDA/EPDM or Viton with metal-to-metal stops for precise compression. Connections are exclusively sanitary Tri-Clamp, SMS, or RJT, and all units are fully drainable in horizontal orientation.

Whether for fluid milk, cultured products, or high-solids concentrates, our heat exchangers meet 3-A, EHEDG, and USDA sanitary criteria while delivering exceptional thermal performance—giving processors complete confidence in product safety and regulatory compliance, year after year.