Dairy Heat Exchangers for White Milk Processing

White milk processing demands high-efficiency heat transfer to achieve safe pasteurization while maintaining flavor, color, and nutritional profile. Plate-and-frame heat exchangers with regenerative sections heat raw milk to 72°C for HTST, recover up to 94% of energy, and cool to 4°C in seconds—ensuring FDA and PMO compliance with minimal thermal damage and extended refrigerated shelf life.

Applications

- Raw Milk Reception & Pre-Heating: Incoming milk is warmed from 4°C to 40°C using heat recovered from outgoing pasteurized milk, reducing energy use by 90%+ in 50,000 L/h systems.

- HTST Pasteurization: Multi-section plate exchangers hold milk at 72°C for 15 seconds, eliminating pathogens while retaining 98% of heat-sensitive vitamins like B12.

- Regenerative Cooling: Pasteurized milk transfers heat to incoming raw milk, then drops to 4°C via chilled water loop, preventing bacterial regrowth and enabling 21-day shelf life.

- CIP Integration: Fully automated clean-in-place cycles with alkaline and acid phases remove milkstone and biofilms, restoring 100% thermal efficiency between batches.

- Homogenizer Integration: Heat exchangers maintain consistent inlet temperatures (55–65°C) to homogenizers, ensuring uniform fat globule size in whole and reduced-fat white milk.

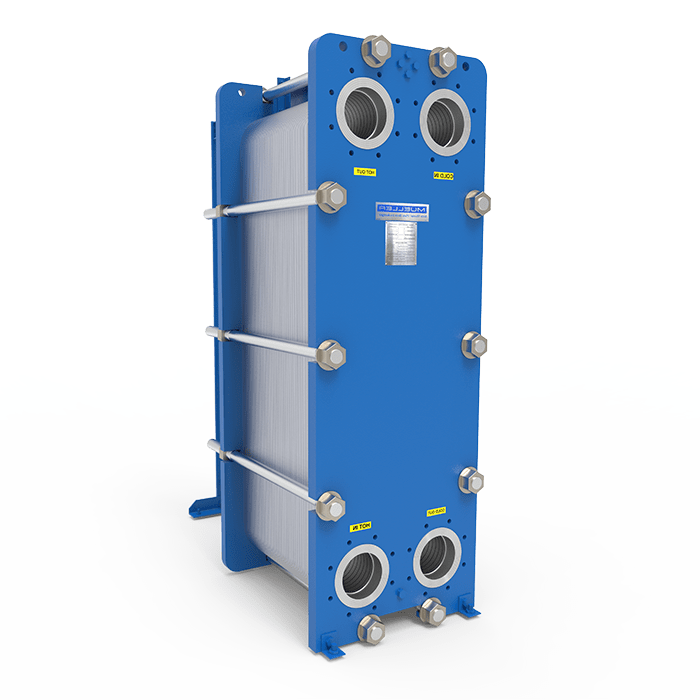

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

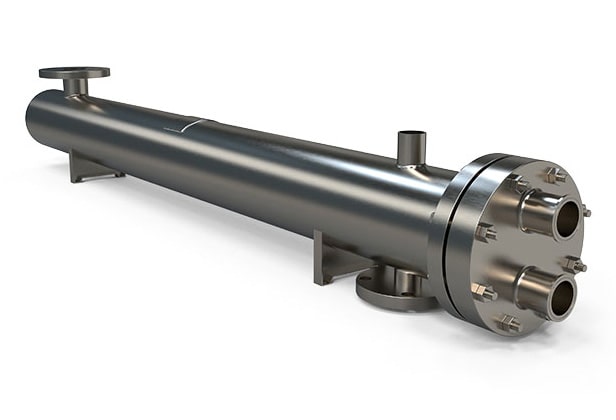

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

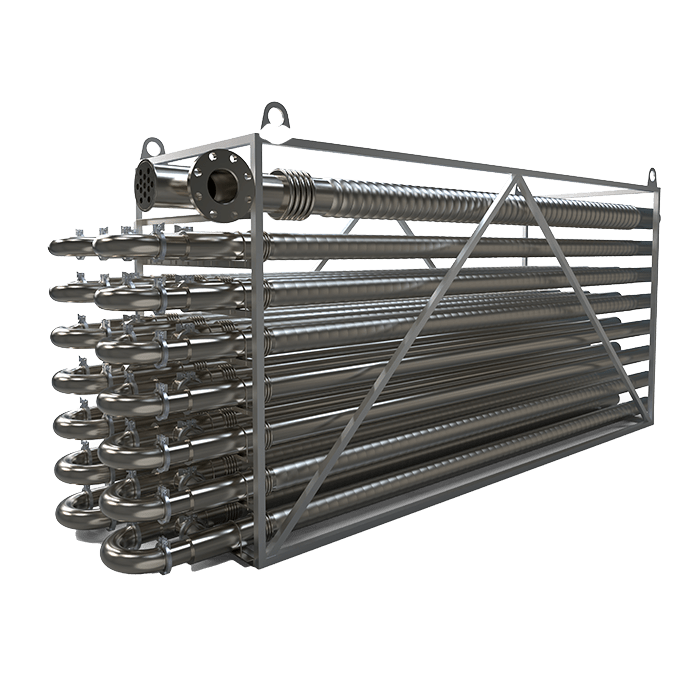

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready

The Benefits of Dairy Heat Exchangers for White Milk Processing

White milk is the cornerstone of fluid dairy operations, and thermal processing directly impacts safety, taste, and profitability. A 120,000 L/day plant reduced pasteurization energy costs by 42% after installing a regenerative plate heat exchanger with 94% efficiency and automated CIP. The system eliminated flavor defects from over-heating, cut water usage by 60%, and achieved zero non-conformances in PMO audits for 24 consecutive months.

These heat exchangers use 316L stainless steel with <0.8 µm Ra surface finish, FDA-approved gaskets, and leak-detect ports to prevent cross-contamination. PLC-controlled hold tubes ensure exact 15-second residence time at 72°C, while real-time temperature logging supports HACCP and electronic batch records. Optional flow diversion valves and booster pumps maintain performance during peak loads.

From small farmstead dairies to national fluid milk brands, our heat exchangers deliver consistent pasteurization, rapid cooling, and full cleanability—ensuring every gallon of white milk meets the highest standards for safety, freshness, and consumer satisfaction.