Glycol Chilling Applications in Dairy Heat Exchangers

Heat Exchangers

The use of heat exchangers in dairy glycol chilling allows for precise low-temperature control, which is critical during rapid cooling to prevent bacterial growth while avoiding freezing.

Rapid Milk Cooling

During dairy processing, milk must be cooled quickly after pasteurization or harvesting. Advantage chillers with glycol loops are known for their precision and reliability, and are often employed in this step. They enable fast and uniform cooling of the milk, ensuring safety and maintaining quality.

Subsequently, controlled chilling is achieved through carefully managed heat removal provided by heat transfer systems. After this, precise temperature control with heat exchangers is necessary to maintain low temperatures, preventing spoilage and ensuring optimal conditions.

Ice Water Generation

In ice water systems for dairy, the heat exchanger is equally important. The control of temperatures influences the creation of near-freezing water without ice formation, directly affecting cooling efficiency. The energy efficiency of heat exchangers, often using glycol as secondary refrigerant, reduces operational costs. Heat exchangers ultimately circulate glycol to produce ice water, delivering effective cooling with their exacting temperature control.

Industry-grade heat exchangers are designed to withstand the demanding environment of dairy plants, where low temperatures and moisture can challenge equipment. These exchangers' durability stands up to the rigorous cleaning chemicals essential for maintaining hygiene standards without compromising integrity.

In dairy production, heat exchangers are more than just equipment; they are central to the science of dairy processing, affecting everything from efficiency and cost-effectiveness to the quality of the final product. Their value in glycol chilling management and energy recovery can't be overstated, making them indispensable in the dairy industry.

Precise Temperature Control

The glycol chilling of dairy products to achieve sub-zero cooling without freezing is another stage where heat exchangers play a key role. Advanced low-temperature transfers performed by these exchangers ensure that products reach the needed conditions without compromising quality or flavor.

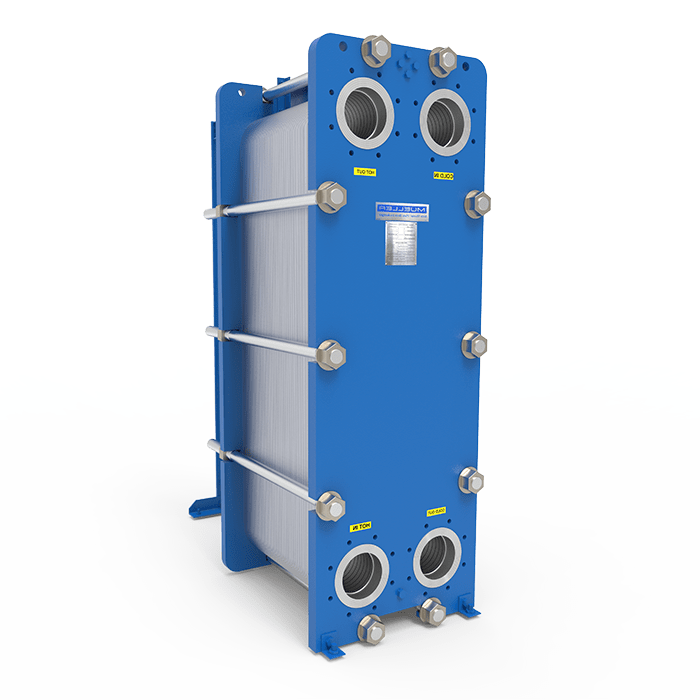

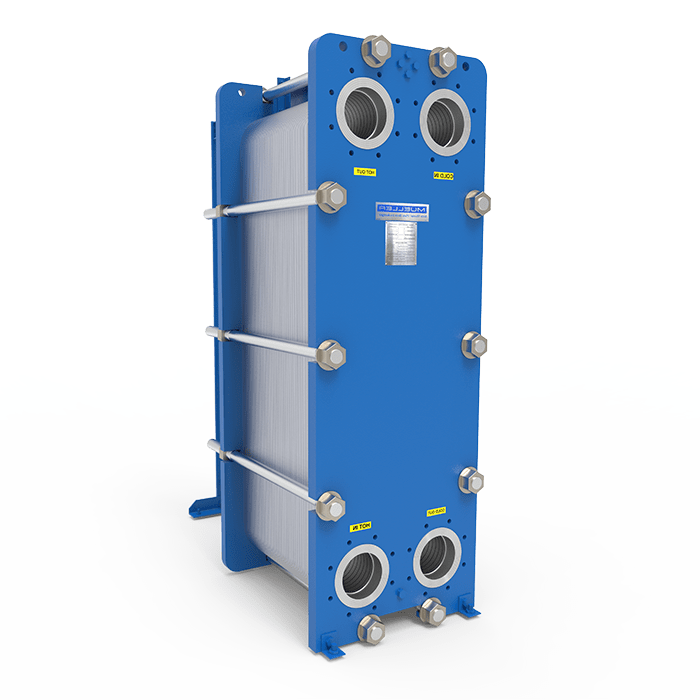

Plate & Frame Exchangers

Compact High-Efficiency Heating & Cooling

- Up to 10,000 L/h Capacity

- Regenerative Energy Recovery

- CIP-Compatible Gaskets

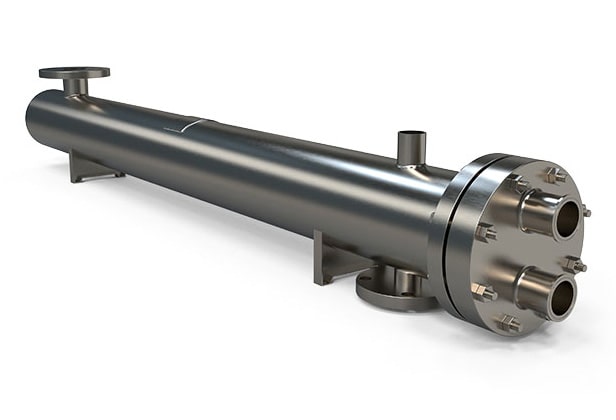

Shell & Tube Exchangers

Robust for Viscous Milk Flows

- Custom Tube Configurations

- High-Pressure Handling

- Sanitary Tri-Clamp Fittings

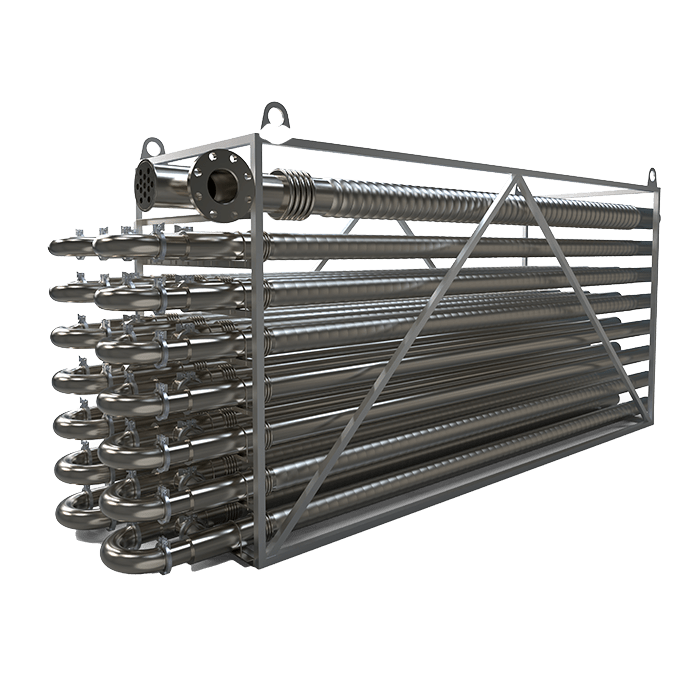

Tube-in-Tube Exchangers

Gentle, Low-Fouling Heat Transfer

- Coaxial Tube Design

- Ideal for Pre/Post-Homogenization

- Fully CIP & 3-A Compliant

Advantage Chillers

Precision Cooling to 0.5°C

- Water or Glycol Systems

- ±0.1°C Temperature Stability

- Stainless Steel & CIP Ready